1219mm Type S Roofing sheet roll forming machine for Saudi Arabia

This roll forming machine is used to produce the Trapezoidal roofing sheet for Saudi Arabia customer.

How to buy this roofing sheet roll forming machine?Contact us!We will produce the machine as your request.Our machines have exported to many countries so we have big experience in the worldwide market,we can give you suggestion or introduction for your market.

Contact person:Judy Liu

Mob/WhatsApp:+86 15127785988(Wechat/Skype)

Email:cnzt003@zhongtuocn.com

Company name:Cangzhou Zhongtuo Roll Forming Machinery Co.,Ltd

Cangzhou Zhongtuo International Trade Co.,Ltd

Website:www.zhongtuocn.com

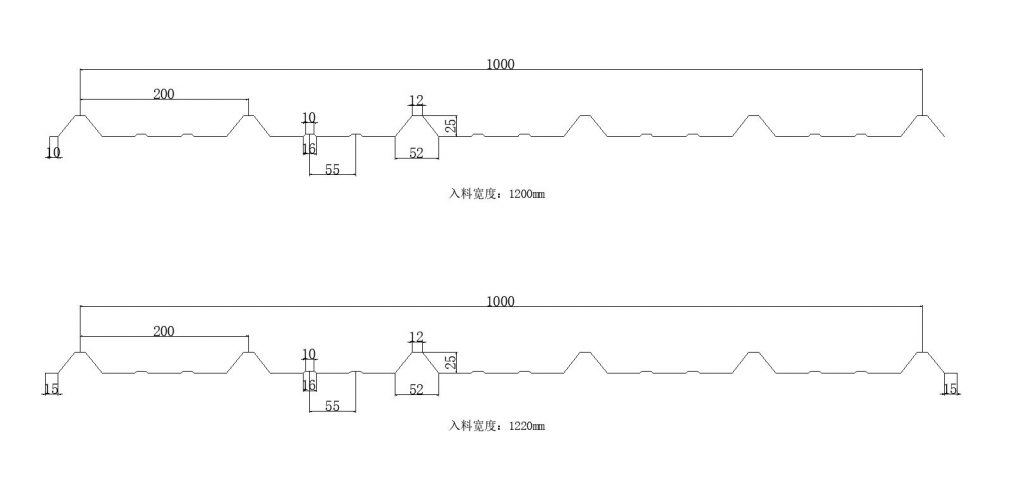

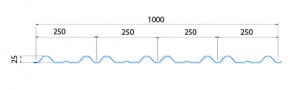

The profile drawing for the1219mm Type S Roofing sheet roll forming machine for Saudi Arabia:

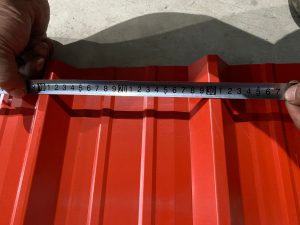

Finished product testing:

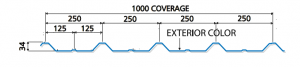

The other profile drawings for the roofing sheet which is used widely in Saudi Arabia:

The installation of the roofing sheet:

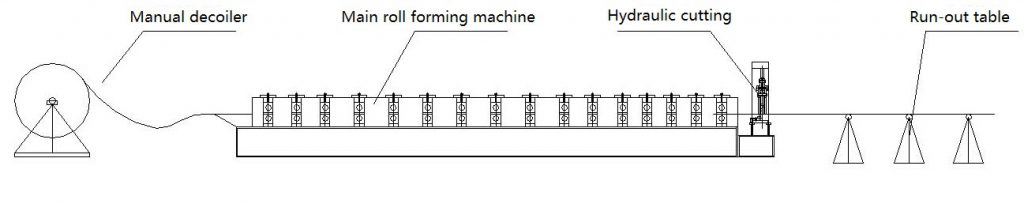

The introduction of the 1219mm Type S Roofing sheet roll forming machine for Saudi Arabia:

The machine is produced as the sizes of the roofing sheet that customers want to produce,the whole production line include:

1.Decoiler/uncoiler:Hydraulic or manaul

2.Main roll former

3.Automatic cutter

4.PLC control system

5.Hydraulic station

6.Product receive table

The layout of the

1219mm Type S Roofing sheet roll forming machine:

The Technical specifications of the machine:

|

Item |

Name |

Specifications |

|

1 |

Raw material |

PPGI,Galvanized steel,Stainless steel |

|

2 |

Raw material thickness |

0.3-0.8mm(Customized) |

|

3 |

Decoiler | Manual/Hydraulic decoiler

Capacity:5-15tons as request |

|

4 |

Roller station |

13 station(according to profile drawing) |

|

5 |

Roller material |

Cr 12 with quenched treatment |

|

6 |

Shaft diameter |

80mm |

| 7 | Shaft material |

45# steel with tempered |

|

8 |

Transmission |

by chain |

|

9 |

Motor power |

5.5kw |

|

10 |

Machine frame |

350H steel welded |

|

11 |

Cutting type |

Hydraulic cutting |

|

12 |

Cutting blade material | Cr12mov with quenched treatment |

| 13 | Cutting tolerance |

+/-1mm |

|

14 |

Control system | PLC |

| 15 | Brand |

PLC:Delta/Siemens/Mitsubishi Touch screen:Delta/Siemens/Mitsubishi Encoder:Omron |

Detailed pictures for each part of machine:

1.Decoiler/Uncoiler for coil

2.Main roll forming machine

3.Control system

4.Hydraulic station

5.Product table

Roofing sheet roll forming machine production video:

http://https://youtu.be/SxA6-_C4xq8