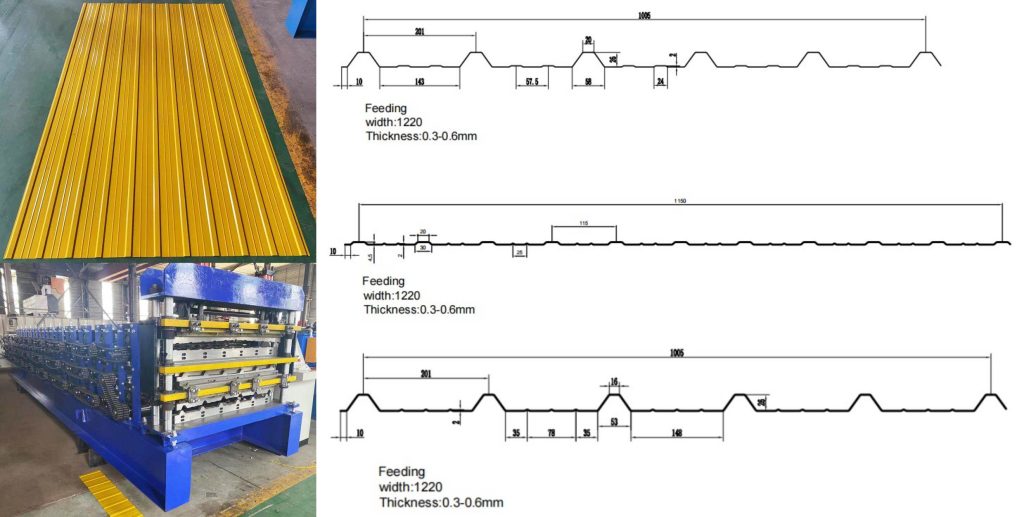

3 Layers Roofing Sheet Roll Forming Machine

3 Layers Roofing Sheet Roll Forming Machine is produced for Saudi Arabic customer.

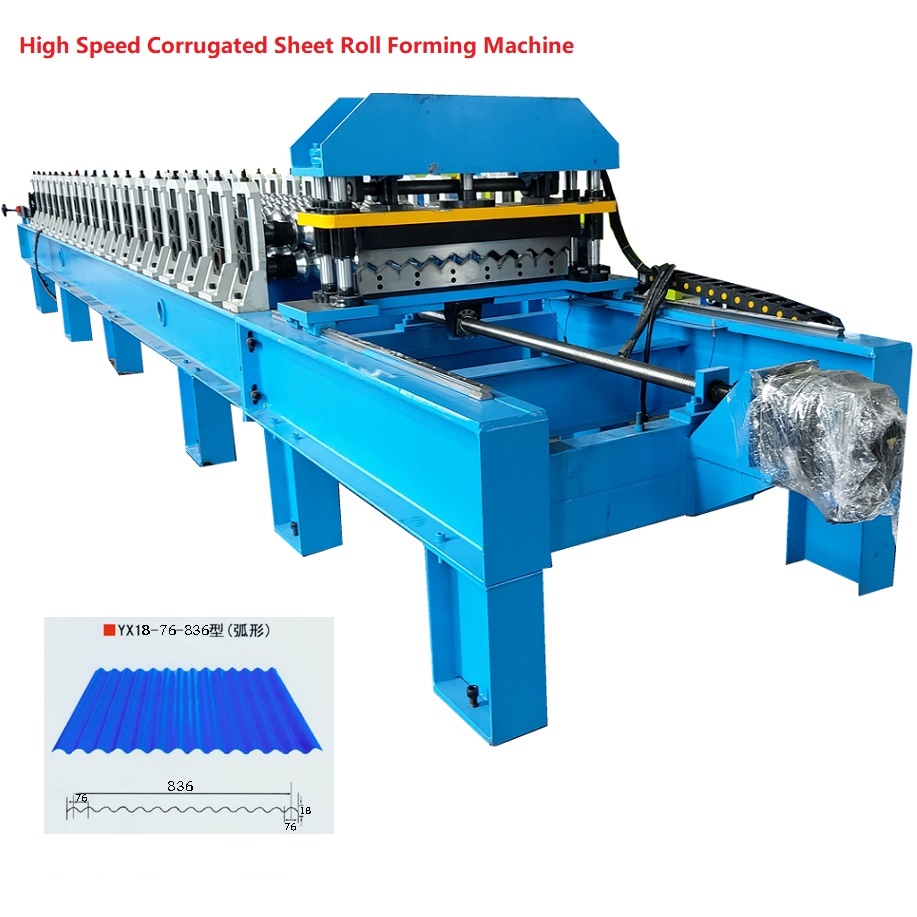

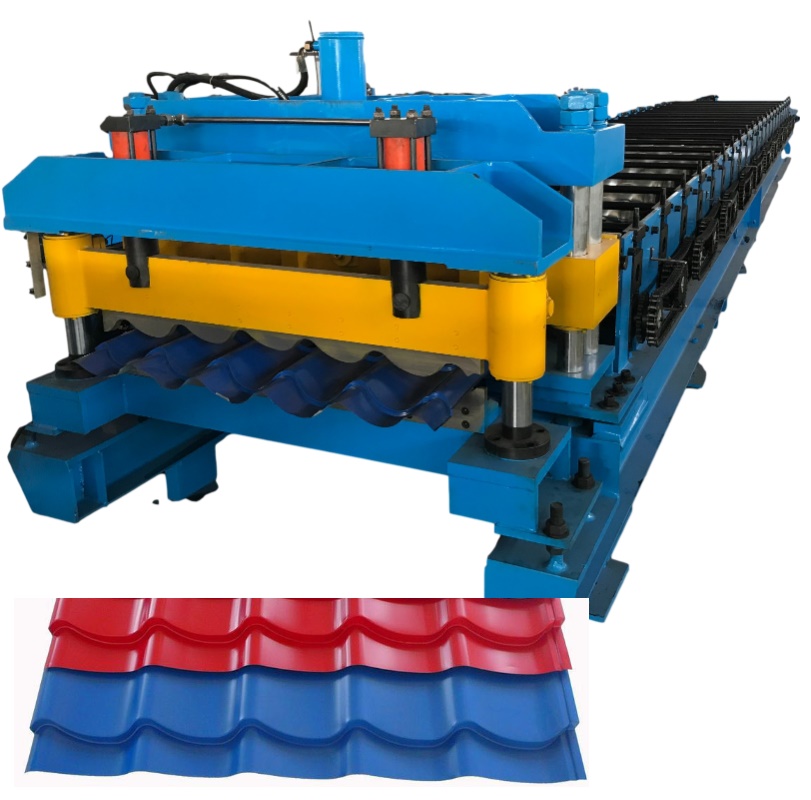

- One machine can produce three different products, such as trapezoidal sheet, corrugated sheet and tile sheet.

- Compare to 3 single machines, this 3 layers machine can save cost and save space for customers

- Suitable for the customer who has limit budget for the machines, and the production quantity request is not very big, because the 3 layers can not work at the same time.

- Perfect finished products can be produced by the machine.

Introduction of 3 Layers Roofing Sheet Roll Forming Machine

Part 1:Decoiler

The capacity of decoiler:For normal coils which is used in roofing sheet,the 5 tons capacity is enough.If customers have special request about the capacity,we also support customization as customer’s request. For the decoiler,we have two types,one is manual and another one is automatic. The different between manual and hydraulic decoiler.

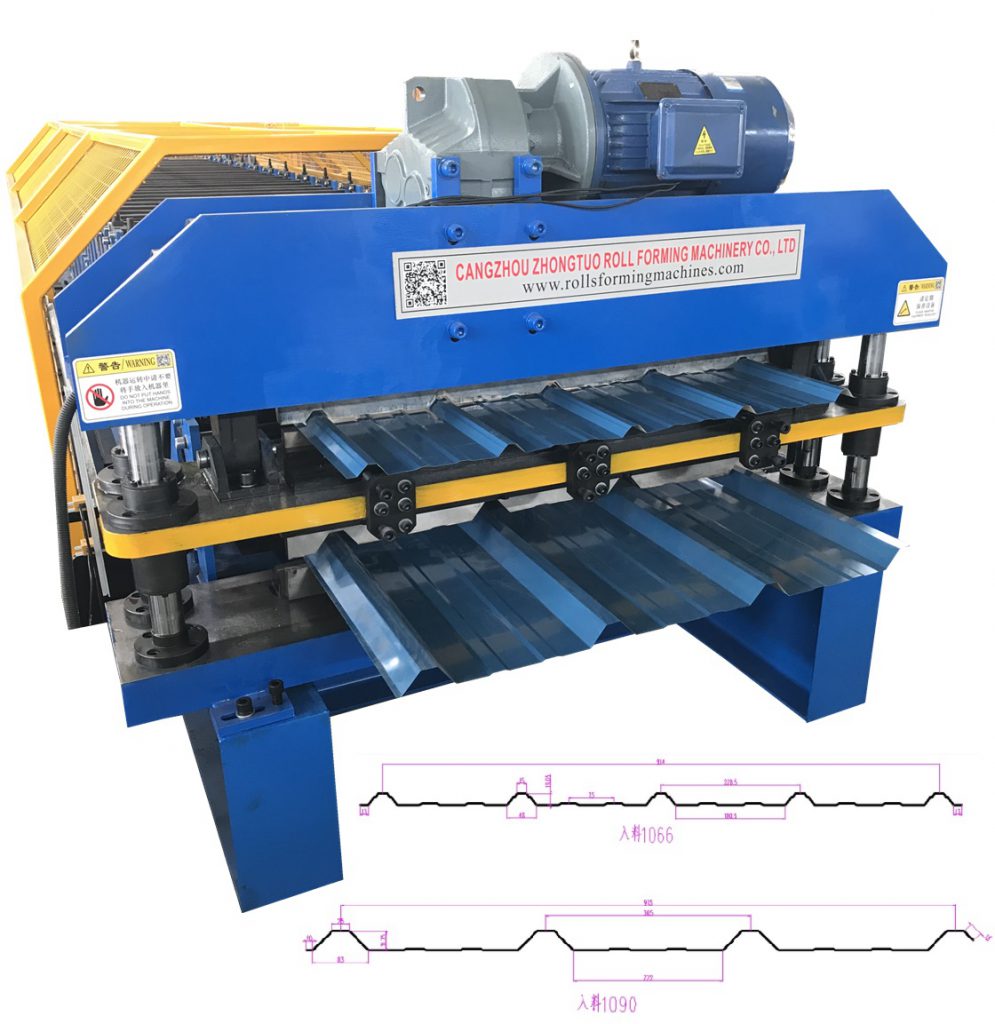

Part 2: The 3 Layers Roofing Sheet roll forming machine

(1) For the feeding part, we use the roller design to protect the surface of the coil.

(2) For the transmission, we use the double chain.

(3) For the base frame, we use the strong with more supporting to make sure the machine working more steady.

(4) For the main motor we use Siemens, if you need we can customize according to your needs.

(5) For the shearing part, we use two pillar supporting shearing to make sure the shearing more accuracy and long time to use.

(6) For the rollers are with the key note and good chroming to make sure long time to use.

(7) We add the clutch in the double layer machine,which can reduce the abrason of the rollers.

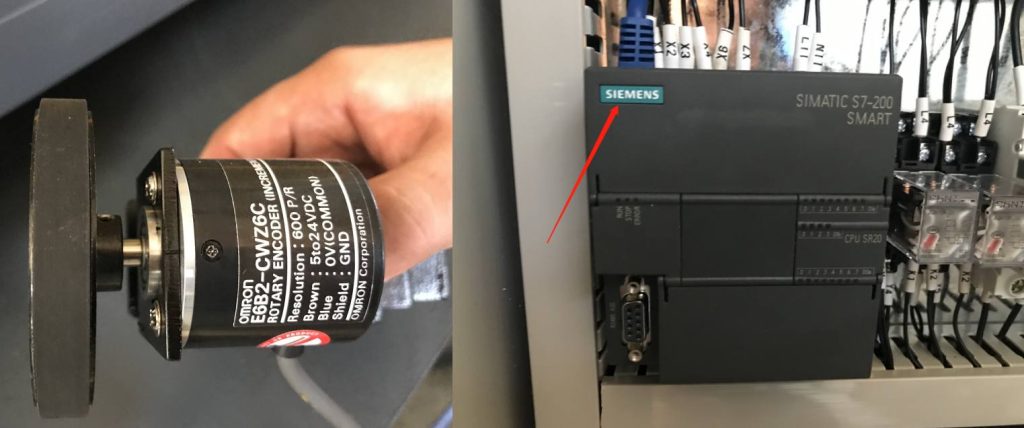

Part 3: Control system

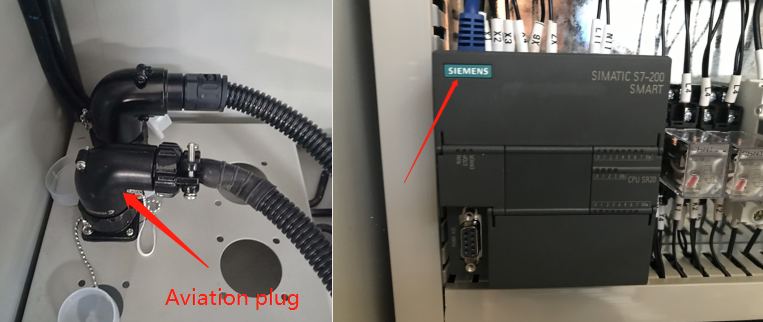

(1) In control system,We use world famous brand Touch screen:Delta,Siemens,Mitsubishi PLC:Delta,Siemens,Mitsubishi Low voltage apparatus:Schneider Encoder:Omron

(2)at the same time, Use aviation plug for customer to easy connection power

Part 4: Hydraulic system

Brand: Beijing Huade, a Chinese famous brand. The magnetic valve features a big valve for good working performance. The cooling system is fan cooling.

Part 5: Product receive table

Type:Roller type up powered(we also have auto stacker for option)

Length:3 meters

Quantity:1 set(according to customer’s request)