30-35m/min High configuration Corrugated Roofing Sheet Metal Roll Forming Machine

- Easy to install and maintain:

Arc tiles are easy to cut and bend, requiring only 2 pieces per square meter for quick installation and minimal maintenance. - Multifunctionality:

In addition to serving as roof tiles, curved tiles can also be used as decorative walls to enhance the aesthetics and functionality of the building. - Environmental protection and durability:

Arc tiles have the characteristics of anti-corrosion and flame retardant, thermal insulation, sound insulation, and green insulation, and have long-lasting color, stable volume, and green environmental protection.

The advantages of the 30-35m/min High configuration Corrugated Roofing Sheet Metal Roll Forming Machine mainly include efficient production, high-quality products, multifunctionality, and economy. This equipment adopts advanced roller forming and pressing technology, which can efficiently produce circular arc tiles with a smooth and beautiful appearance, uniform paint patterns, and high strength. It is widely used in the construction of industrial and civil building surfaces and walls.

Other attributes:

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:0.3-0.8mm Width:1000mm/1250mm(customized)

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

16 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

350 H steel

|

|||

|

Drive

|

Gearbox transmission

|

|||

|

Dimension(L*W*H)

|

8500*1600*1600(customize)

|

|||

|

Weight

|

7.5T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

11KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

30-35m/min

|

The speed is adjustable as customer’s request

|

||

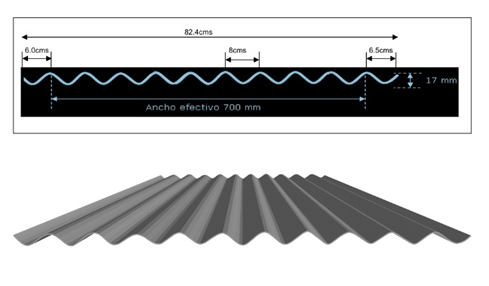

Profile drawing:

Details of the 30-35m/min High configuration Corrugated Roofing Sheet Metal Roll Forming Machine:

Packing Style:

Packing method :Main body of machine is naked and covered by plastic film(to protect of dust and corrosion),oaded into container and steadily fixed in container suitable by steel rope and lock, suitable for long-distance transportation.