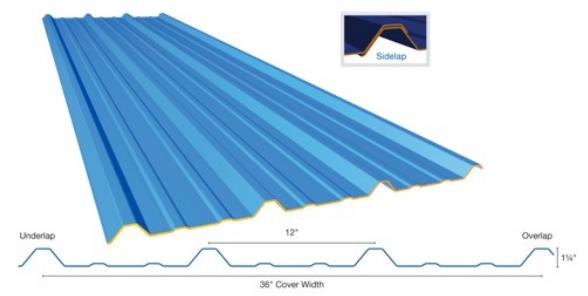

36” R panel Roll Forming Machine for USA market

4 Rib 36″ x 1 1/4″ High Ribs

• Computer batch control

• Hydraulic Shear

• Includes 11,000 lb manual uncoiler(5 TONS,Also have hydraulic decoiler)

• 220V 3 phase

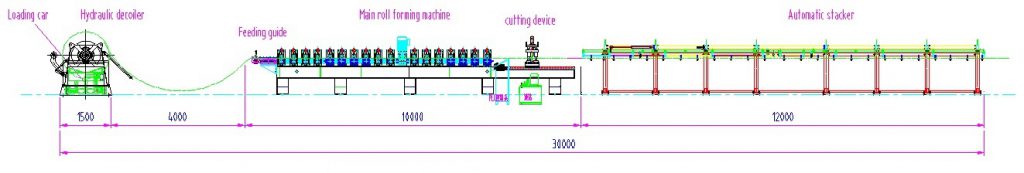

The components of the 36” R panel Roll Forming Machine for USA market

1.Manual/Hydraulic decoiler

2.R panel roll former

3.Hydraulic shear system

4.PLC control system

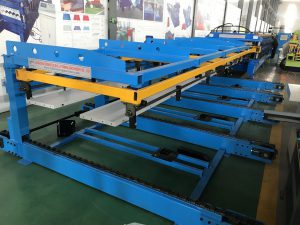

5.Product receive table/automatic stacker

The layout of the Machine

The technical specifications

Part 1:Hydraulic decoiler/Manual decoiler

- Capacity:5 tons/11000 lbs

- Coil width:max 1200mm or as per request

- Coil inner diameter:470mm-530mm

Part 2: R panel roll former

- Machine frame:350# H steel,with cast iron memorial arch

- Roller station:16 stations

- Roller material:45# steel with quenched treatment,chromed in the surface

- Shaft material:45# steel with heat treatment

- Shaft diameter:80mm

- Motor power:11kw

- Transmission:by gearbox

Part 3:Hydraulic shearing system

- Shearing type:Hydraulic

- Blade material:Cr 12 with quenched treatment

- Hydraulic power:7.5kw

- With fan cooling system

Part 4:Control system

- Control system:PLC

- Function:Length,batch and speed control

- Touch screen brand:Delta/Siemens/Mitsubishi

- PLC brand:Delta/Siemens/Mitsubishi

- Encoder:Omron

- Low pressure apparatus:Schneider

Part 5:Automatic stacker

- Length:6m/9m/12m as customer’s request

- Working type:Pnuematic

Machine working video

Related roll forming machines: