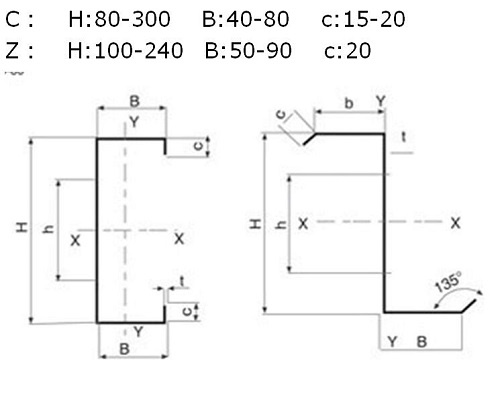

C Purlin Z purlin roll forming machine

Machine introduction:

This machine is to produce the C and Z shape which is used in Purlin and other place,they can be produced in one machine in a very simple adjust way.The width,webs and flanges sizes can be changed as customer’s request.This machine also can punch holes in the product,the hole’s location and quantity can be customized as request.

The standard sizes for the C purlin and Z purlin is as below,the sizes can be customized as customer’s request too.

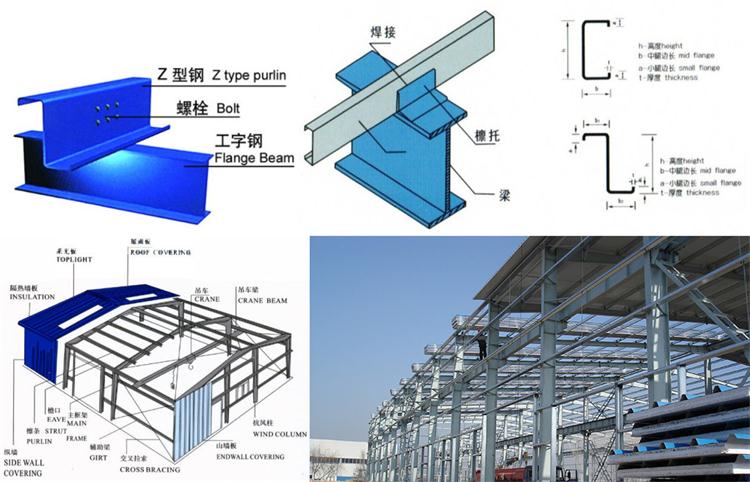

The application of the C purlin and Z purlin:

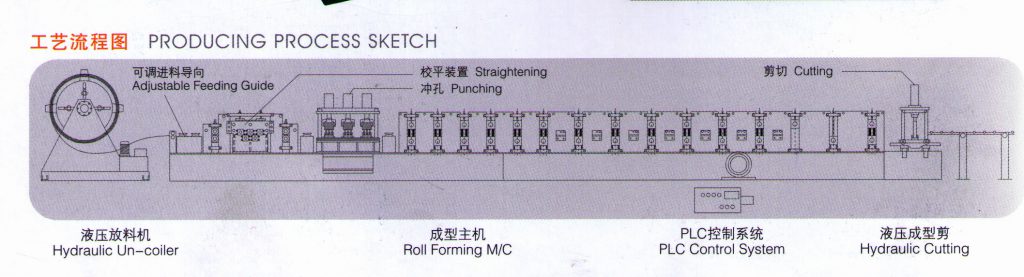

The layout of the C Purlin Z purlin roll forming machine:

The technical specifications of the C purlin Z purlin roll forming machine:

| Main machine parameters:

Machine voltage: 380V, 50hz, 3 phase Material thickness: 1.5-3.0 mm, yield strength≤G345Mpa Processing material: PPGI,GI, Q345, HR steel etc. |

|

| Working Flow:

Decoiler- feeding- leveling – roll forming- – punching- cutting- receiving table |

|

| Machine components:

Manual decoiler 1 set; Main roll forming machine (feeding – leveling-punching – roll forming- cutting) 1 set; Hydraulic station 1 set; Control computer 1 set; Receiving table 2 sets; Maintain tools 1 set; Instruction manual 1 brochure. |

|

| Manual Decoiler System | Loading capacity: 5 t

Uncoiling width: 500 mm Inner diameter: 450-550 mm |

| Feeding and Flatten | Feeding rollers+guiding rollers

Flatten:Up three down four additional two stations guiding and sending, full solid shaft heat treatment with blasting and chroming. |

| Main roll forming system | Main forming: 18 stations forming (inside 1 station for forming flange, 87-95 degree adjustable), 13 stations CZ change mould, turnover 180 degree to finish the change. Changing the Specification size by means of an electric button.

Rib forming: Straight rib. Straighten: 10 rollers CZ special-use double axis straightening and 4 rollers Double axis straightening, total 2 straightening units. Guiding and sending: Driven by up and down gears. |

| Punching system | 2 Punching device,one is for bottom and another one is for waist

Hole’s size can be customized as request Hole’s length and be adjusted |

| Cutting System

|

It employs post-cutting, hydraulic drive and automatic

location to decide the dimension and cut target products, ensure stability, precision and cutting speed. Cutting type: after forming stop cutting Power supply: hydraulic power Material of blade: Cr12mov quench treatment Length measuring: automatic encoder measuring Tolerance of length: 3000mm± 1.0mm For cutting blade, you can manually adjust the cutter to cut different sizes of c z purlin. NO need to change new blade and this cutter is easy to operate. |

| Receiving Table | Frame: weld by angle steel and square tubes, on the top with support rollers.

Table type: no power Diameter of rollers: 55mm Table size: 3.0 x 1.0 x 0.9m Quantity: 2 sets |

| Control station | Main control cabinet: 1 set

Change way: (motorized) change model, (3pcs of motors: 0.75Kw*3) Change wiring box: 1 piece (installed in the middle of machine) External controller: 1 piece (to control the running direction forward or back during the testing or production manually) Main electrics origin: PLC (Japan Omron), touch screen (Xinjie), relay (Japan Omron), proximity switch (Korea Autonics), encoder (Japan Omron) |

| Hydraulic station | Hydraulic tank: motor power 22Kw

Tank volume: 500L Maim component origin: magnetic valve Beijing HUADE Hydraulic motor: out five-start piston rod |

The pictures of the C purlin Z purlin roll forming machine:

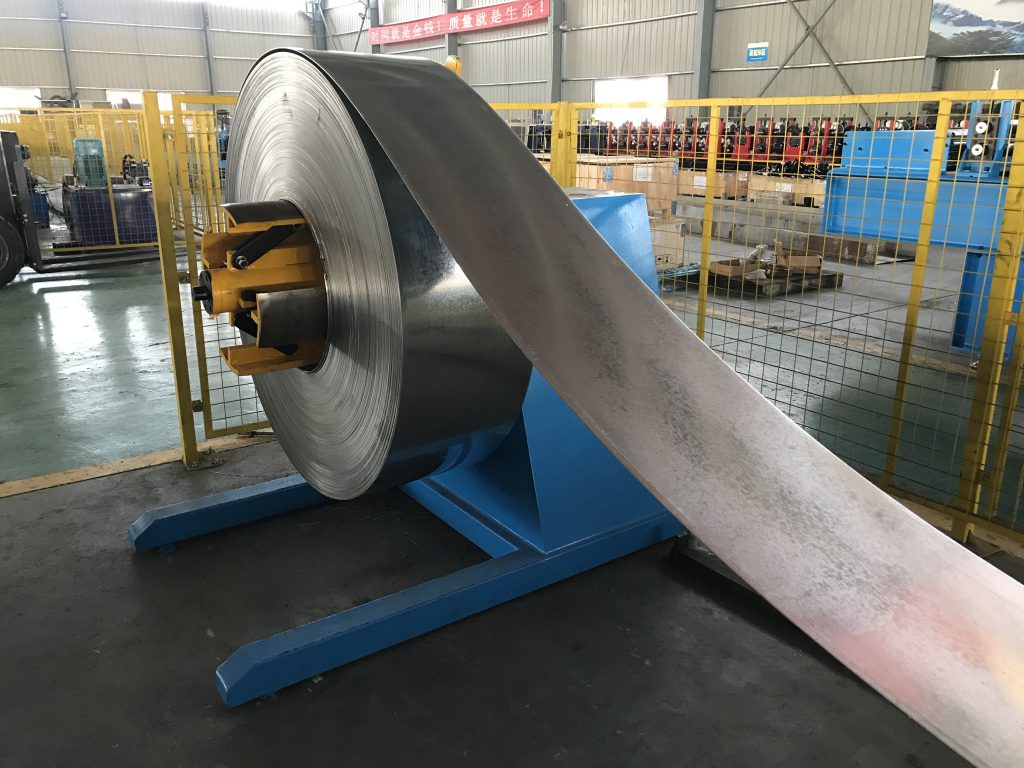

1.Decoiler

2.Feeding and leveling part

3.Punching device

4.Roll former

5.Cutting device

6.Finished product

C purlin Z purlin roll forming machine’s working video:

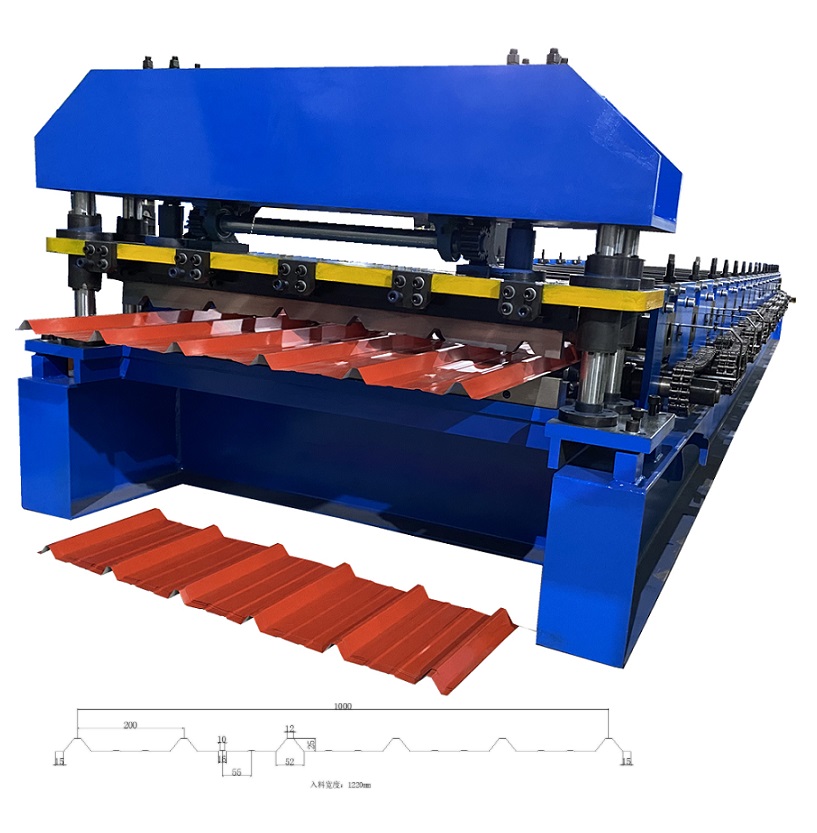

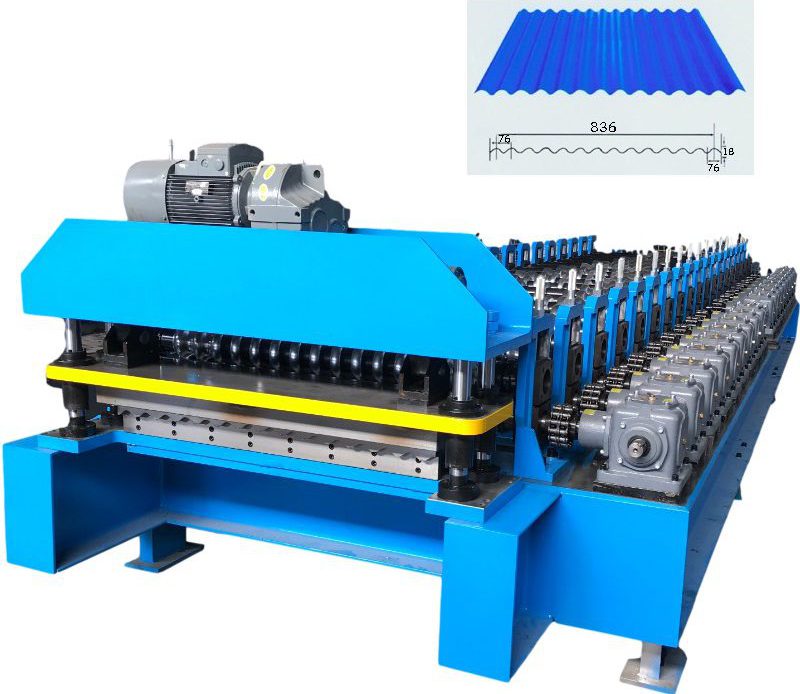

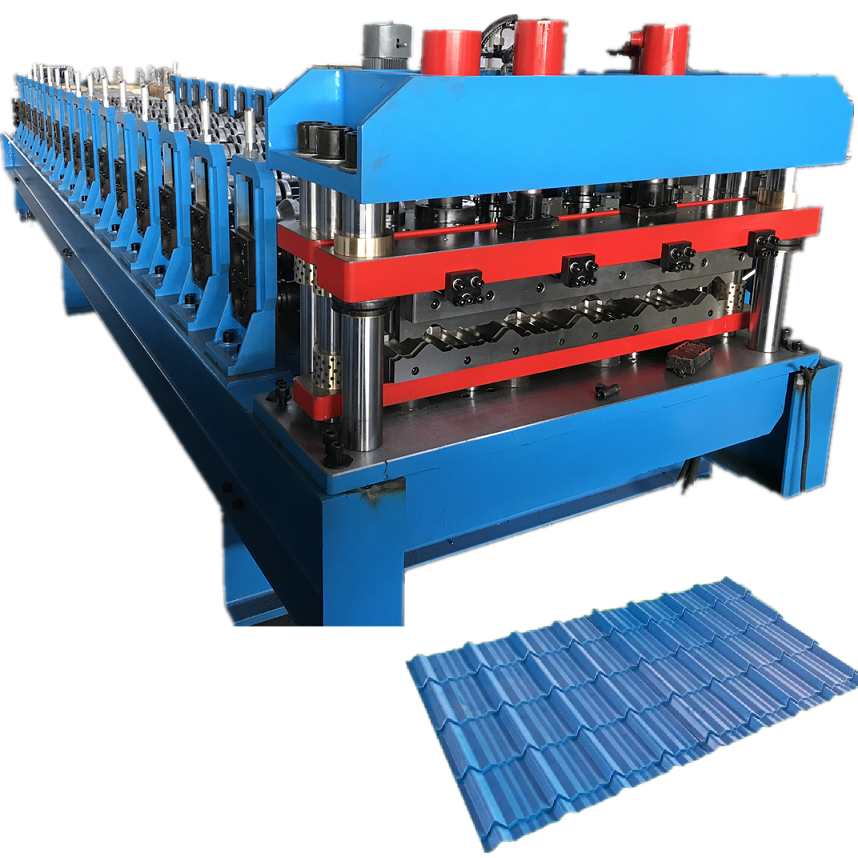

Related roll forming machines: