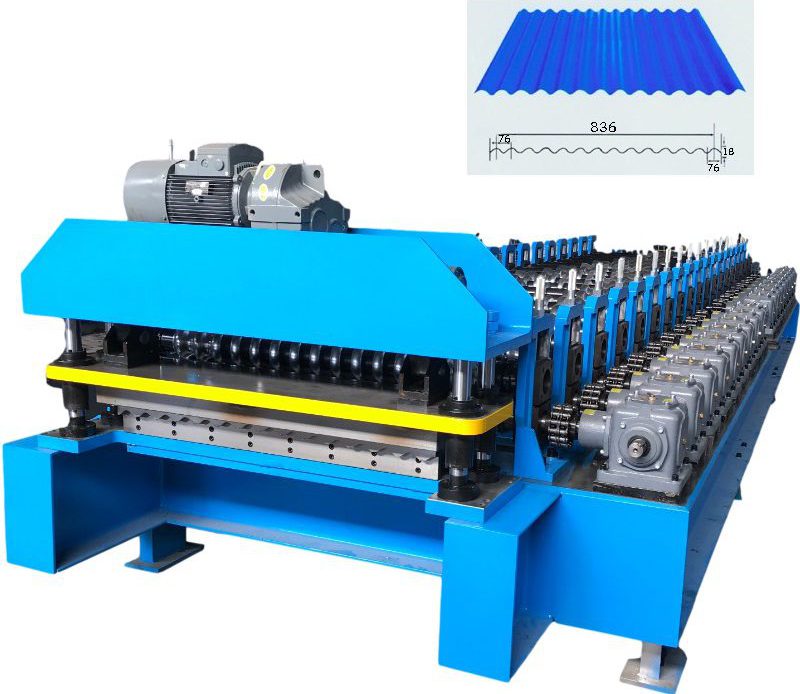

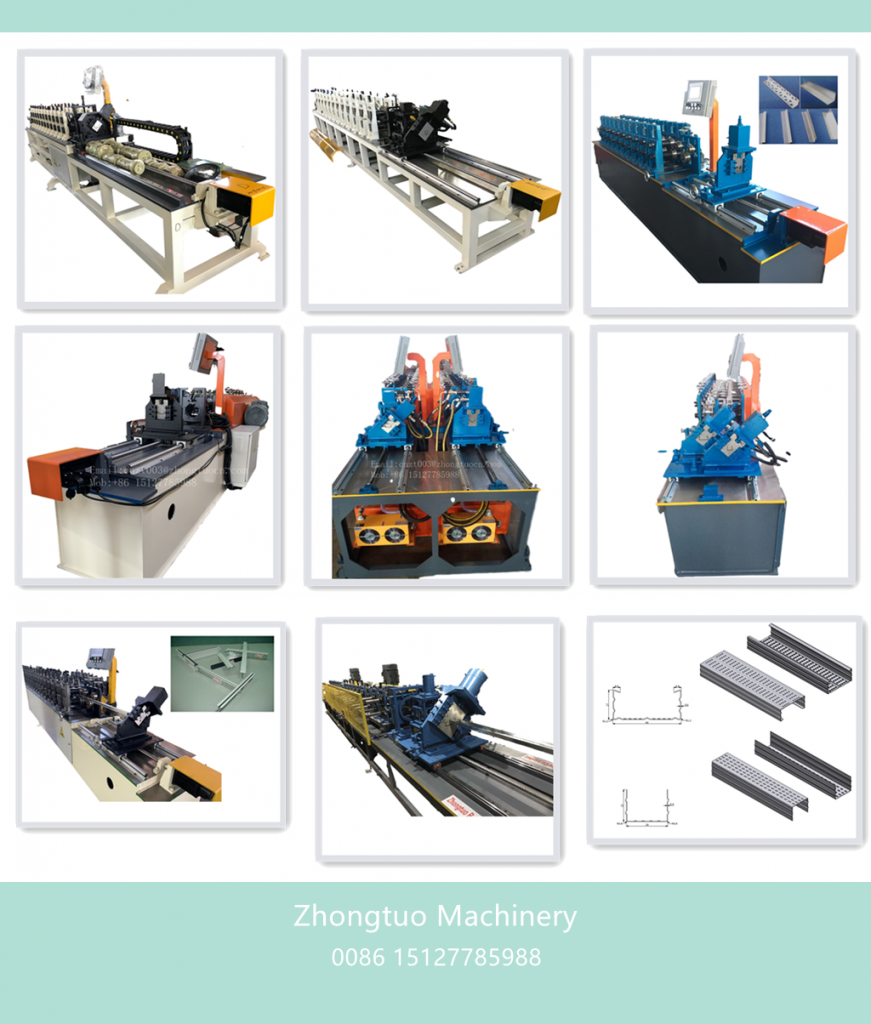

36 inch R panel Roll Forming Machine for USA Market

36 inch R panel Roll Forming Machine for USA Market is the machine to produce the R panel, which is used a lot in USA.

The main description of the 36 inch R panel Roll Forming Machine for USA Market:

1. Hydraulic decoiler

- Equipped with hydraulic decoiler with loading car, capacity 5-10 tons, as per customer’s request.

- Equipped press arm which used to keep the coil from loosing.

- Equipped with supporter which can carry the heavy coils.

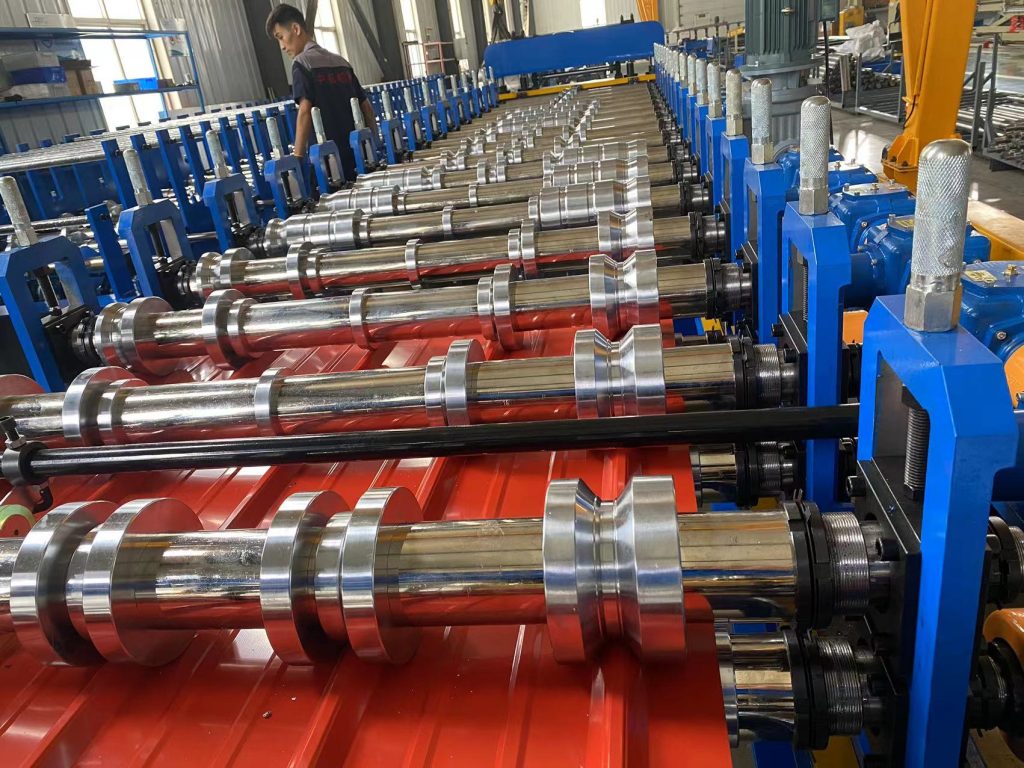

2. Main Roll Forming Machine

- Gearbox transmission

- Iron cast molding frame structure: High precision, working stable and long life-time.

- Hydraulic pre-cutter which can reduce the waste of the material when changing coils.

- Roller shaft diameter: 80mm, solid shaft.

- Roller material: 45# steel, surface is chromed.

- With the keyway on the rollers and shaft.

- Motor power: 7.5 kw

- Bearing brand: SKF

3. Hydraulic cutting system

- Hydraulic station is equipped with acculator which can improve the cutting speed.

- Cutting type: Hydraulic pre-cutting and post cutting.

- Cutting blade material: Cr12 Mov, withe quenched treatment.

- Famous brand hydraulic parts.

- Equip with fan cooling system.

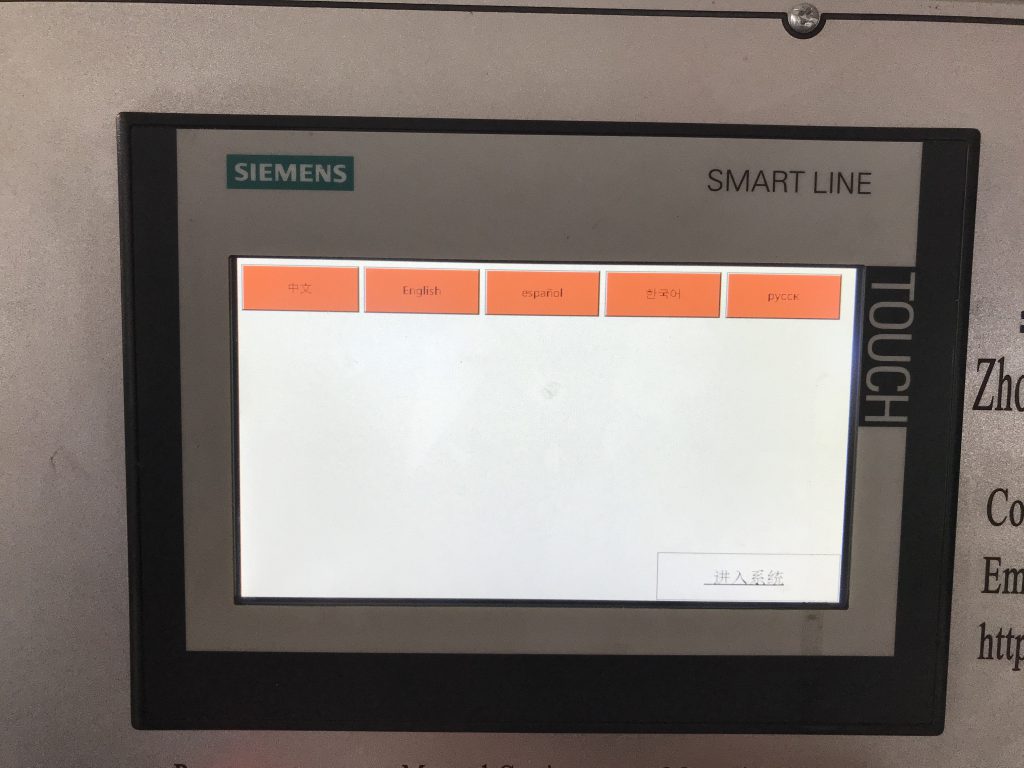

4. Control system

- Screen brand: Delta, Siemens Mitsubish for operational.

- PLC brand: Delta, Siemens Mitsubish for operational.

- Language: Chinese, English, Spanish, Arabic, France and so on.

5. Automatic stacker

- Length: 3-12 meters, depends on customer’s request.

- Working type: Automatic receive the sheet and stack orderly.

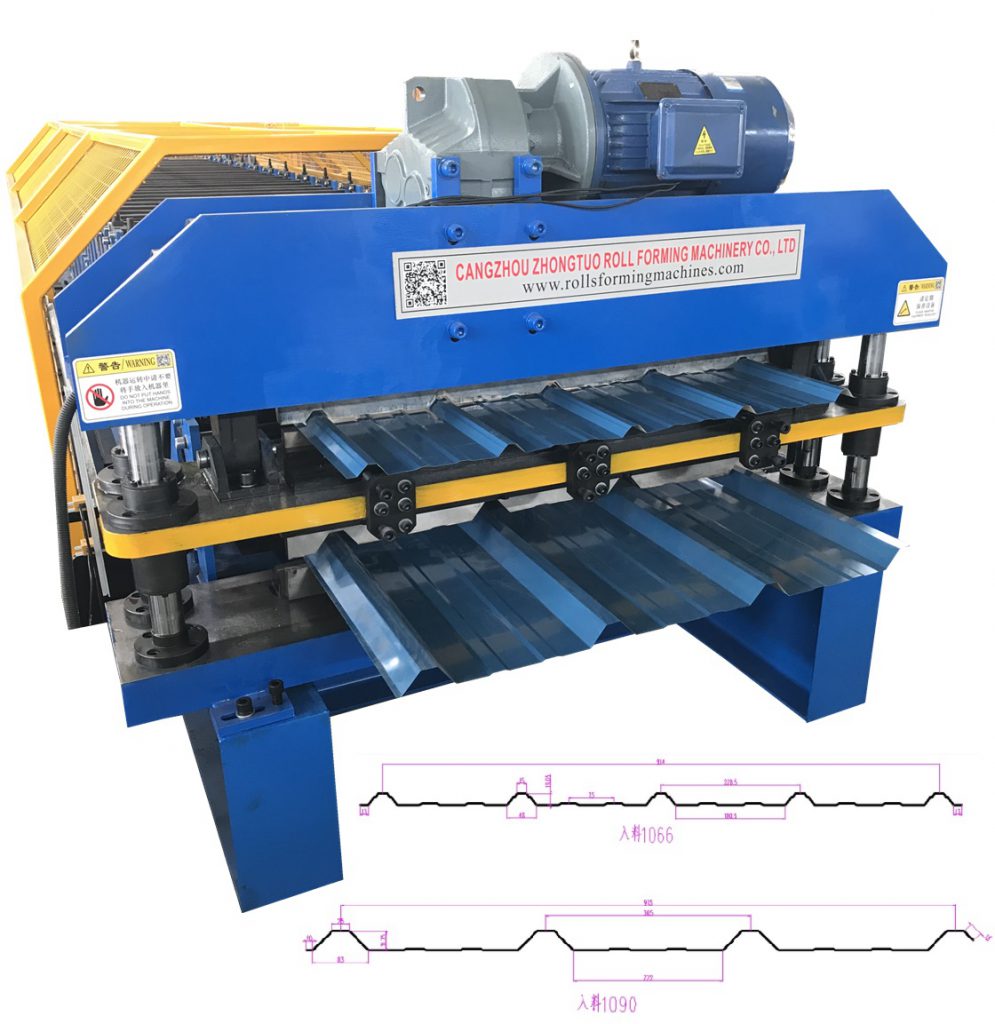

Related Roofing Sheet Roll Formig Machine:

Other Cold roll forming machines: