Downspout Roll Forming Machine is the machine to produce the downspout, our machine is customized as the customer’s request.

Features of Downspout Roll Forming machine:

- Can produce different materials: PPGI and Aluminium

- Can produce different shapes: Round downspout or square downspout

- With elbow function.

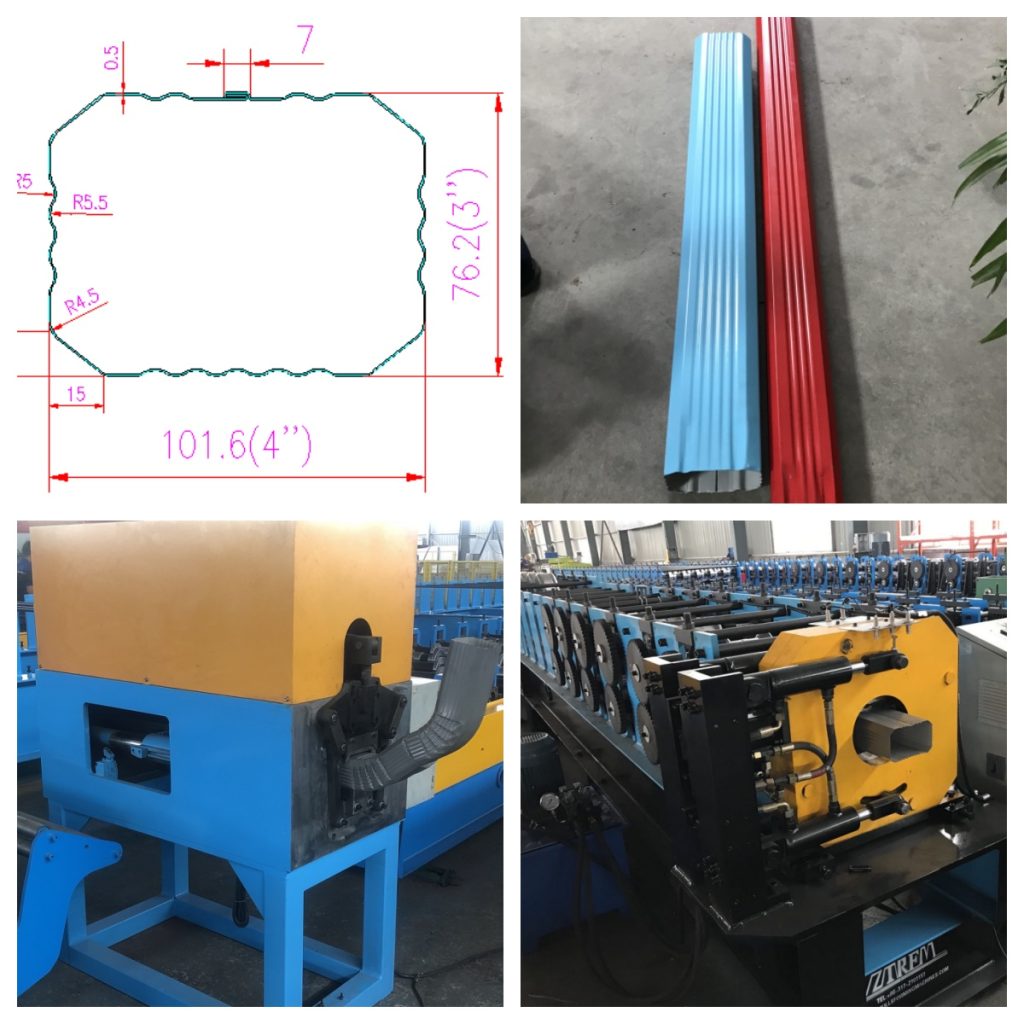

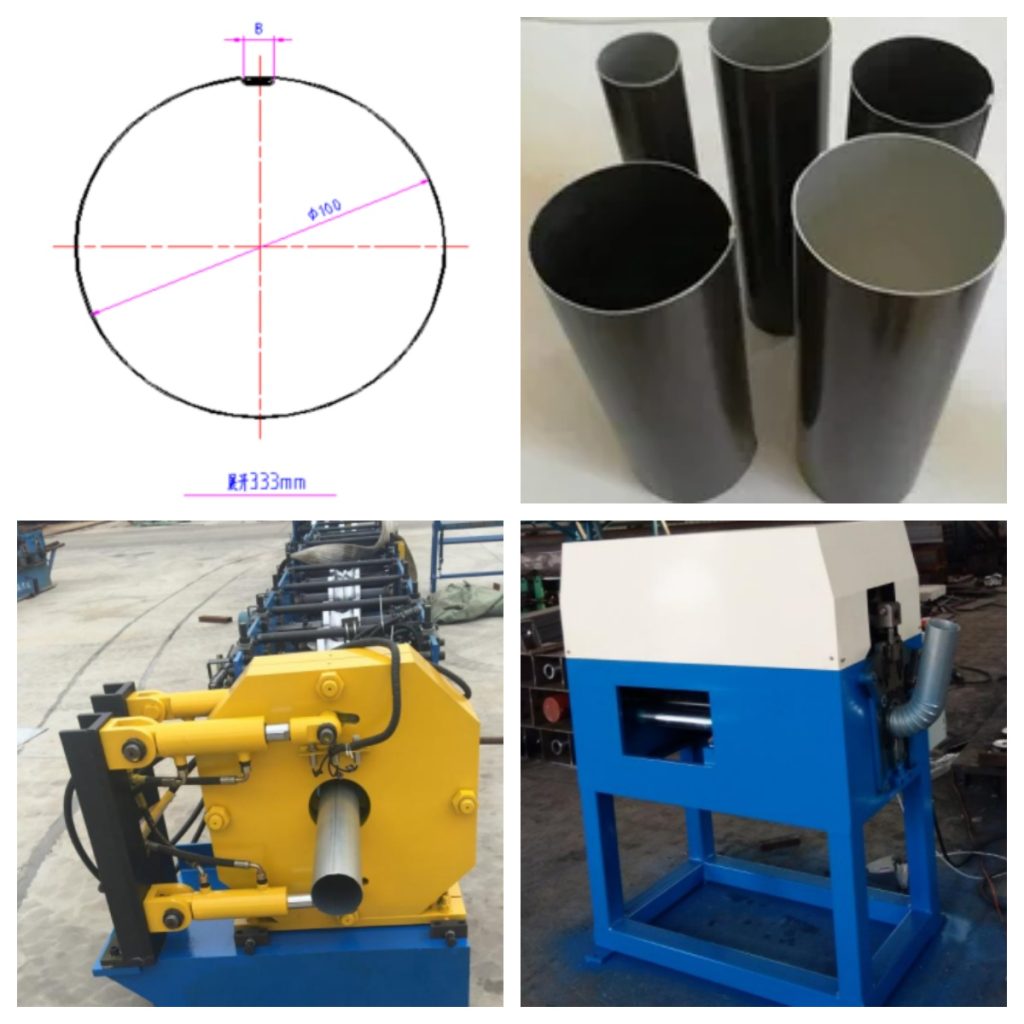

The downspout profile drawings:

Square downspout: can be different sizes.Round downspout: can be different sizes.

Round downspout: can be different sizes.

The introduction for different Downspout Roll Forming Machine designs

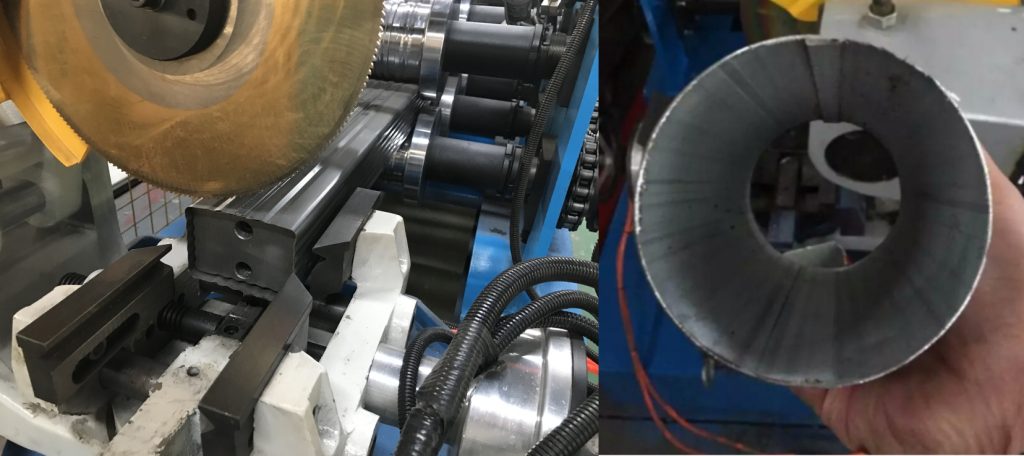

1.For the machine’s structure

- Middle wall plate welded: The most used, the most common

- Iron cast molding frame structure, with chain transmission: Machine is more stronger, working more stable and higher precision too.

2.For the cutting type

- Hydraulic cutting, almost no burrs

- Flying saw cutting: Low cost, no distort, speed slow.

3.Elbow type:

- An individual elbow: Working efficiency is a little low, need more man-power. Machine’s cost is lower.

- Integrated roll forming and elbow: High working efficiency, save labor. Machine’cost is a little higher.

About us

We understand trade regulations and related formalities to ensure that the export process is legal and compliant. We can help customers with export licenses, customs declarations, commodity inspections and other procedures.

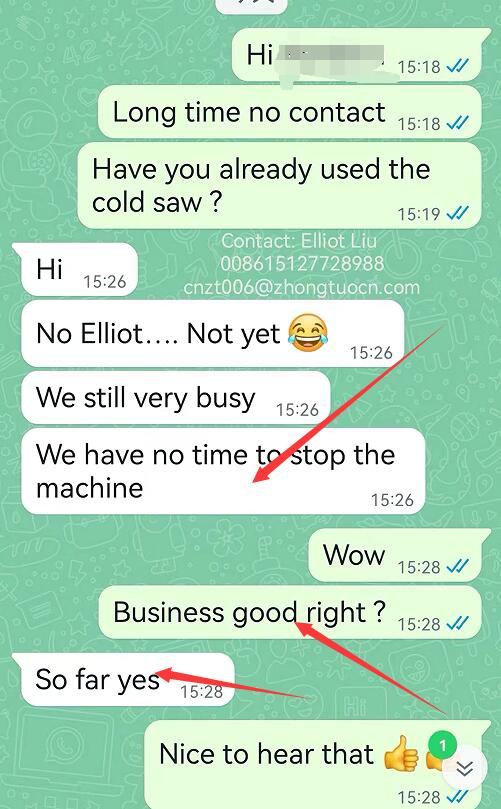

Provide technical support and after-sales service, including installation and commissioning guidance, operation training, spare parts supply and timely maintenance services. This helps customers to be able to solve problems in a timely manner when they encounter them during use.

Application of Downspout Roll Forming Machine

Recommonded similar machine: