The IBR sheet roll forming machine is designed for the fully – automatic batch production of IBR sheets. First, I’ll introduce what an IBR sheet is and what it looks like.

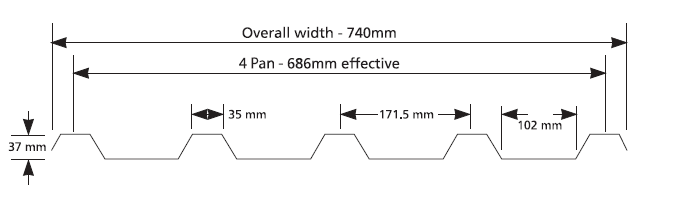

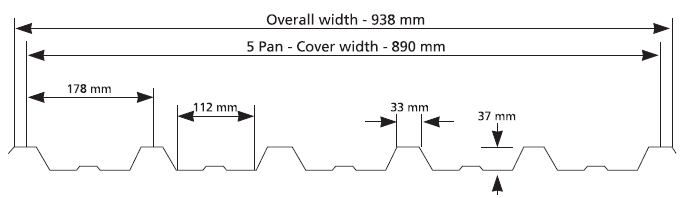

Since its introduction to South Africa in 1958, IBR has been widely popular as a side cladding or roofing material in commercial, industrial, and residential buildings. IBR is named after the abbreviation of “Inverted Box Rib” and has become a well – known term in the South African building industry. In fact, IBR is a square fluted profile with an effective covering width of either 686 mm or 890 mm.

ZT has several customized designs of IBR Sheet Roll Forming Machines for IBR sheeting. Our IBR Sheet Machine can form IBR sheets with a G550 Mpa strength and a thickness of up to 0.8 mm. We also have a Corrugated Sheets Roll Forming Machine for South African customers.

Some popular drawing off IBR sheet roll forming machine or example:

686 IBR profile:

890 IBR profile:

Main Parameters of IBR Sheet Roll Forming Machine:

| Coil Thickness | 0.3-0.8mm |

| Feeding Width | 925mm, 1219mm |

| Effective width | 686mm, 890mm |

| Forming Speed | 10-15m/min |

| Forming Stations | 24 stations |

| Diameter of Shafts | 76mm |

| Material of Shafts | high quality 45# steel |

| Material of Rollers | Cr40, chromed 0.05mm with hardness treatment. |

| Transmission | chain-sprocket transmission |

| Motor Power | 7.5KW |

| Cutting Type | hydraulic cutting, stop-cutting |

| Material of Cutting Blade | Cr12Mov, quenching and tempering HRC60-62 |

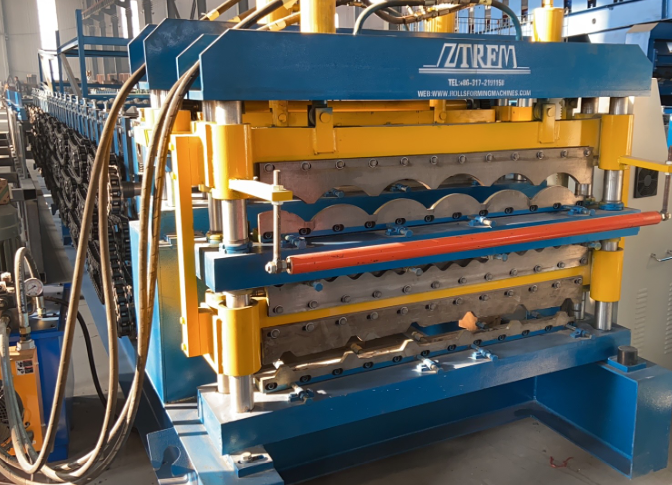

we have three options for your reference: first that you can make single IBR sheet by single machine, second you can choose two make double layer roofing sheet machine third you can choose to make triple layer machine. For example:

This is an example of three layers:

This is the machine of two layers:

Single Layer IBR sheet roll forming machine:

Similar to other roll forming machines, IBR Sheet Machine consists of decoiler, guiding device, roll former, hydraulic cutter controlled system and product output table. And Auto Stacker is an option.

Recommend related machine: