In the field of modern architecture, color coated roof panels are favored for their beauty, durability, anti-corrosion and other characteristics. And color coated roof panel roll forming machine is the key equipment for producing these high-quality roof panels.

Features of Color Coated Roof Panel Roll Forming Machine

- High-precision

Advanced molding technology and a precision rolling system ensure that the dimensional accuracy of the roof panel reaches the millimeter level, ensuring the installation quality of the roof.

- Efficient production

The automated production process greatly improves the production efficiency. A color coated roof panel forming machine can produce a large number of roof panels in a short time to meet the needs of large construction projects.

- Diversified product specifications

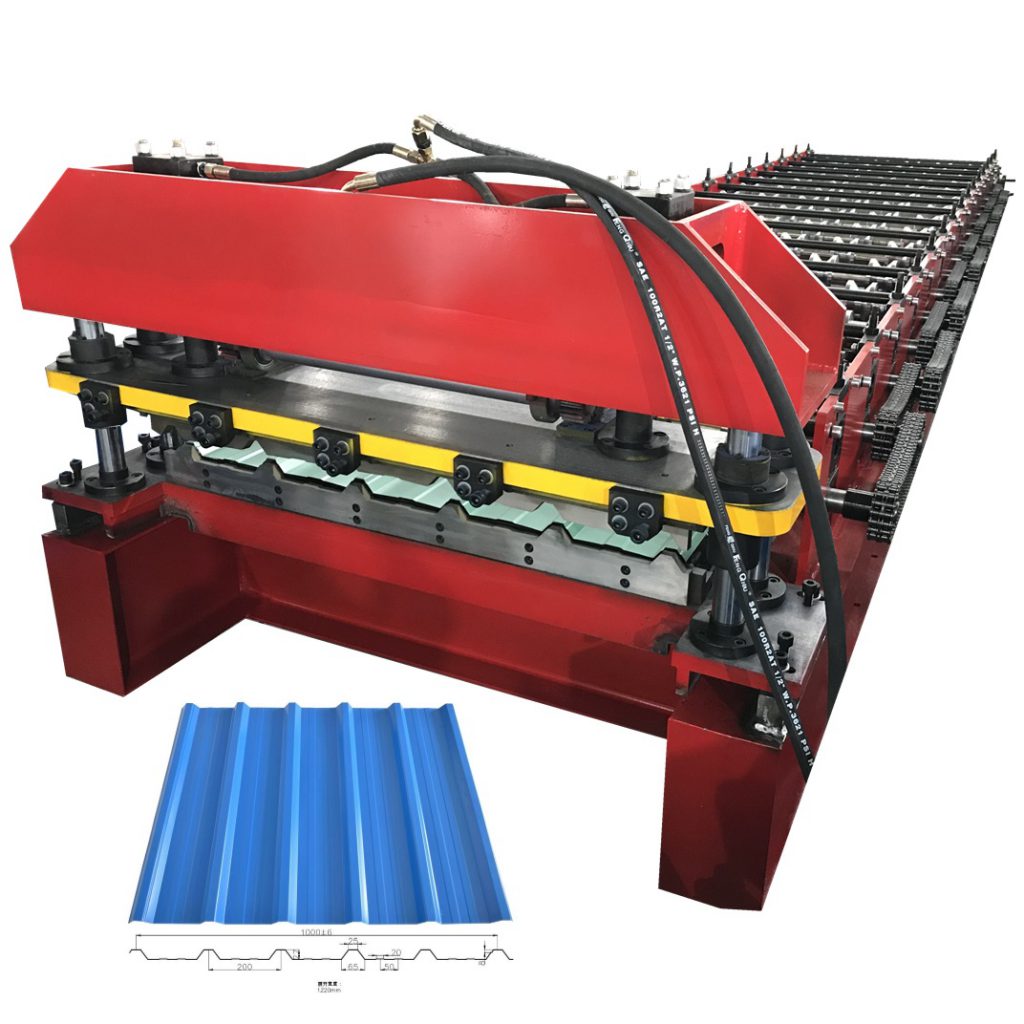

We can design the machines to produce color-coated roofing panels of various shapes, sizes and thicknesses according to different architectural design requirements to meet the individual needs of different customers.

- Energy conservation and environmental protection

In the production process, the color coated roof panel roll forming machine adopts advanced energy-saving technology to reduce energy consumption. At the same time, the color coated steel plate itself has good environmental performance and can be recycled and reused.

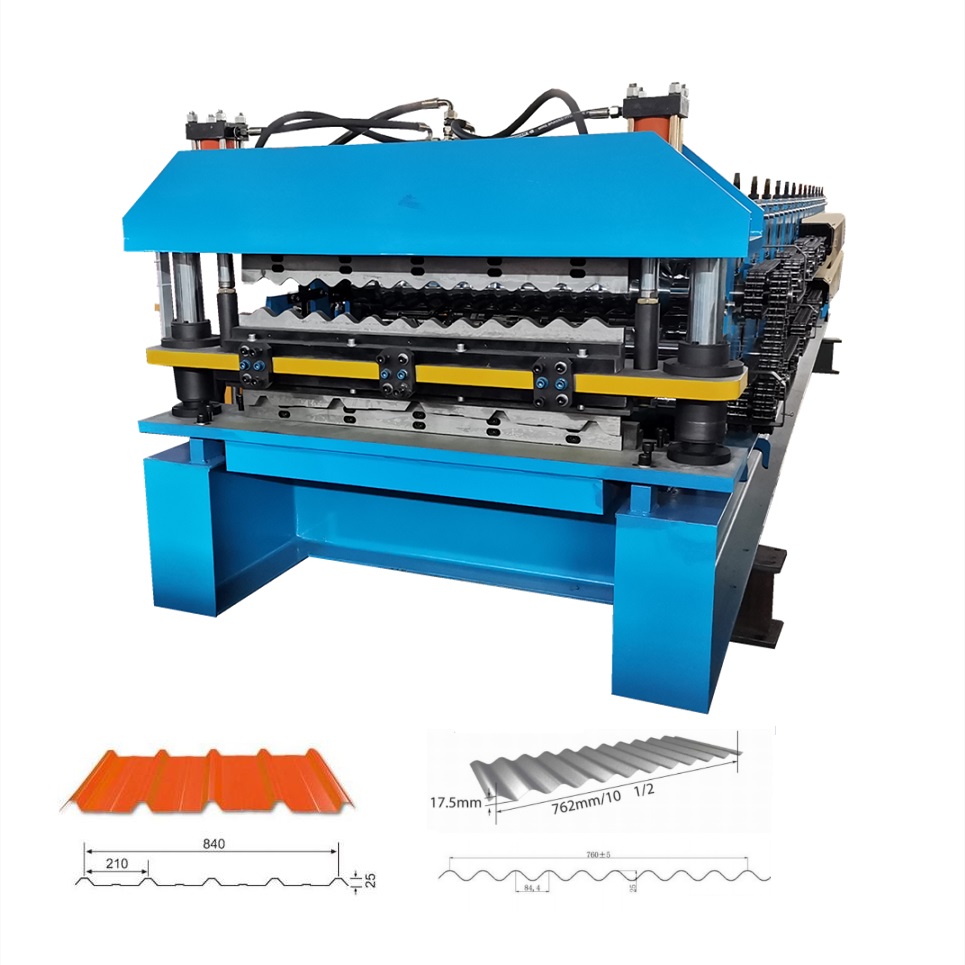

Today, let me show the Color Coated Roof Panel Roll Forming Machine to you:

1.This panel profile consists of only three peaks, yet these peaks are relatively high. To guarantee the perfection of the panel profile, there are numerous roller stations, making the machine relatively long in length.

2.To save space, the hydraulic station and the control cabinet isinstalled on the upper part of the forming machine; the control cabinet is installed on side of the basic frame;

3.The design of the rocker-type touch screen also saves space

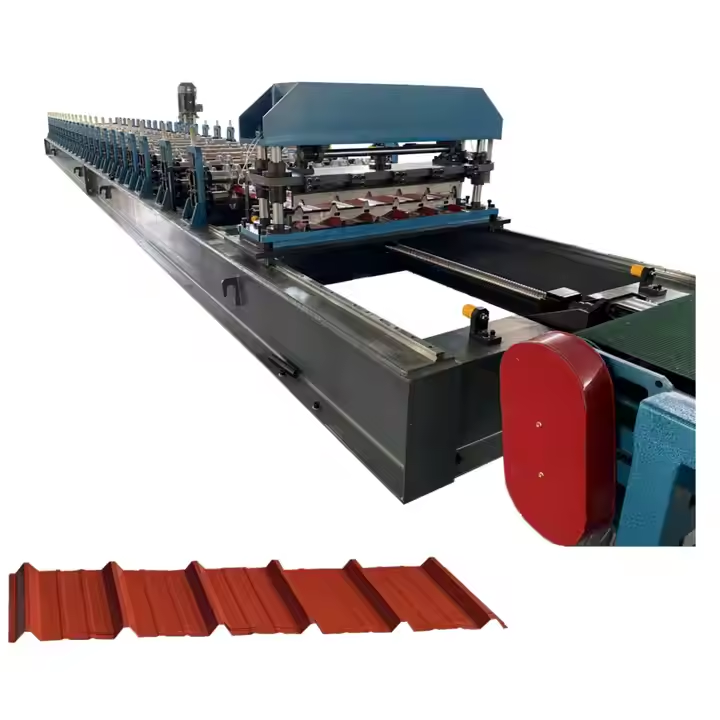

4.The feeding parthas a manually material cutting design, which can cut off the material at any time and has the advantage of reducing material waste.

5.Double-cylinder cutting head design:provide better stability during the shearing process;maintain more precise cuts and less waste of materials.

Recommend related machine:

We have more than ten years of experience in manufacturing cold – bending forming equipment. If you need cold – bending forming equipment, you can consult us at any time.