This machine is a floor decking forming machine produced for our UAE customer.The ZT-1220 floor decking forming machine provides important support for construction by efficiently producing high-quality floor slabs, while reducing costs and improving the overall performance of the building. Widely used in steel structure buildings such as industrial plants, sports venues, large supermarkets, logistics centers, etc.

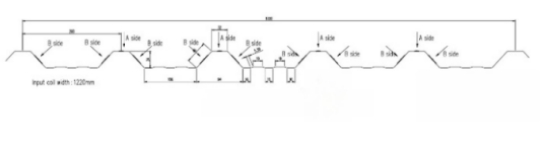

The profile drawing:

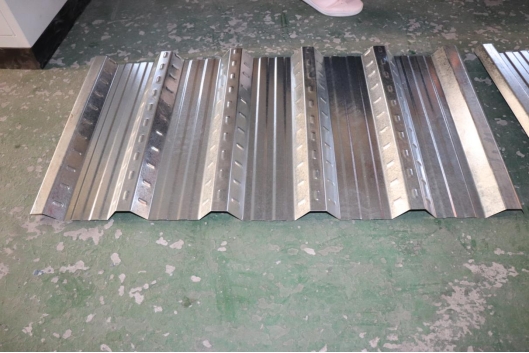

The pictures for the finished product:

Production process:

Uncoiler-Feeding material into machine→Roll forming→hydraulic cutting→ Products receiving.

Packing list of the ZT-1220 floor decking forming machine:

| No. | Name | Quantity |

| 1 | Manual/hydraulic Decoiler | 1 set |

| 2 | Main roll former | 1 set |

| 3 | Control system | 1 set |

| 4 | Hydraulic system | 1 set |

| 5 | Product Run-out table | 1 set |

The technical specifications of theZT-1220 floor decking forming machine:

| Item | Name | Specifications |

| 1 | Raw material | GI&PPGI |

| 2 | Raw material thickness | 0.5-1.0mm |

| 3 | Decoiler | 5T |

| 4 | Felt device | Available |

| 5 | Roller station | 24stations |

| 6 | Roller material | 45# steel |

| 7 | Shaft diameter | 85mm |

| 8 | Shaft material | 45# steel |

| 9 | Transmission | By double chains |

| 10 | Motor power | 5.5kw |

| 11 | Machine frame | 400H steel |

| 12 | Cutting type | Hydraulic cutting |

| 13 | Hydraulic power | 5.5kw |

| 14 | Cutting blade material | Cr12 quenched |

| 15 | Cutting tolerance | +/1mm |

| 16 | Control system | Delta/ Siemens PLC |

The function of ZT-1220 floor decking forming machine:

1. High precision machining:

The equipment adopts CNC technology with high machining accuracy, which can ensure that the size, shape, and surface quality of the floor slab meet the design requirements.

2. Energy conservation and environmental protection:

The ZT-1220 floor decking forming machine focuses on environmentally friendly design, using low-energy motors and transmission systems to reduce energy consumption and noise.

3.Easy to operate and safe:

The operation interface of the device is simple and clear, and operators can proficiently operate it after simple training. At the same time, multiple safety protection devices are equipped to ensure the safety of operators.

4.Strong durability:

The equipment is made of high-strength steel, which has high strength and durability, and can meet the needs of large-scale construction projects.

5.Construction advantages:

The floor slab can serve as a sturdy work platform during the construction phase, supporting the flow construction of multi-layer laying and layered pouring of concrete, accelerating the construction progress. During the usage phase, floor slabs can also serve as tensile steel bars for concrete floor slabs, improving their stiffness and load-bearing capacity.

Some details of the ZT-1220 floor decking forming machine:

Our company Cangzhou Zhongtuo Roll Forming Machinery Co.,Ltd and Cangzhou Zhongtuo Internation Trade Co.,Ltd is the professional manfacture for the Roll forming machines,especially Roof and wall sheet roll forming machine, floor deck roll forming machines, CZ Purlin roll forming machines,Floor Decking Forming Machine light gauge drywall stud and track roll forming machines and so on.