The 80-250 C Purlin Making Machine shapes raw materials (such as steel plates) into the desired C-shaped steel shape through forming parts, including forming wheels and molds.The formed C-shaped steel needs to be cut according to actual usage requirements to ensure that its length meets the standard. The cutting part of the 80-250 C Purlin Making Machine is responsible for cutting the formed C-shaped steel into the required length, usually achieved through high-precision cutting tools and equipment to ensure cutting accuracy and quality.

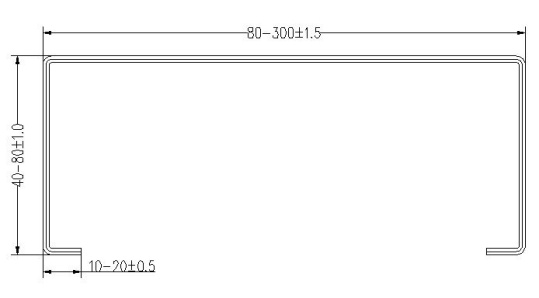

The profile drawing:

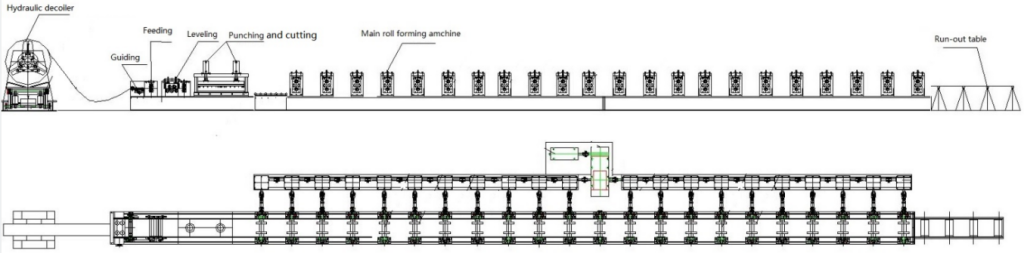

Production process:

Uncoiler-Feeding material into machine→Roll forming→hydraulic cutting→ Products receiving

|

Packing list of the 80-250 C Purlin Making Machine :

| No. | Name | Quantity |

| 1 | Manual/hydraulic Decoiler | 1 set |

| 2 | Main roll former | 1 set |

| 3 | Control system | 1 set |

| 4 | Hydraulic system | 1 set |

| 5 | Product Run-out table | 1 set |

The technical specifications of the 80-250 C Purlin Making Machine:

| Item | Name | Specifications |

| 1 | Raw material | GI&PPGI |

| 2 | Raw material thickness | 1.0-3.0mm |

| 3 | Decoiler | 5T |

| 4 | Felt device | Available |

| 5 | Roller station | 18stations |

| 6 | Roller material | GCr15, heat treatment and hard chrome-plated ,HRC55-58 |

| 7 | Shaft diameter | 80mm |

| 8 | Shaft material | S45C, heat treatment HRC42 |

| 9 | Transmission | By double chains |

| 10 | Motor power | 15kw |

| 11 | Machine frame | 4000H steel |

| 12 | Cutting type | Hydraulic cutting |

| 13 | Hydraulic power | 11kw |

| 14 | Cutting blade material | Cr12 quenched |

| 15 | Cutting tolerance | +/1mm |

| 16 | Control system | Delta/ Siemens PLC |

The function of the 80-250 C Purlin Making Machine:

1. Efficient production:

The 80-250C Purlin Making Machine adopts advanced processes and technologies, which can quickly and massively produce C-shaped steel to meet market demand. Its high production efficiency enables large-scale industrial production, effectively reducing production costs and improving market competitiveness.

2.Stable product quality:

The 80-250C Purlin Making Machine ensures stable and reliable product quality, and the produced C-shaped steel has good strength and durability. It has a high degree of automation, is easy to operate, and reduces manual errors and labor intensity.

3.Flexible adjustment:

This equipment can flexibly adjust production parameters to meet the production needs of different specifications and sizes of C-shaped steel, and has strong universality. It has a high degree of automation, is easy to operate, and reduces manual errors and labor intensity.

4.Energy conservation and environmental protection:

The 80-250C Purlin Making Machine has a very reasonable structural design, occupies a small space, and is easy to install and maintain. In the production process, it can effectively save raw materials, reduce production costs, and meet the requirements of modern society for sustainable development.

5.Wide application:

C-shaped steel is widely used in fields such as construction and steel structures, and its unique properties make it an ideal choice for these industries. C-shaped steel serves as the main load-bearing structure for large and medium-sized industrial and civil buildings, such as factory buildings, warehouses, locomotive depots, aircraft hangars, exhibition halls, cinemas, sports venues, and market flower sheds, with roof load-bearing capacity and wall level support.

Some details of the80-250 C Purlin Making Machine:

Our company Cangzhou Zhongtuo Roll Forming Machinery Co.,Ltd and Cangzhou Zhongtuo Internation Trade Co.,Ltd is the professional manfacture for the Roll forming machines,especially Roof and wall sheet roll forming machine, floor deck roll forming machines, CZ Purlin roll forming machines,Floor Decking Forming Machine light gauge drywall stud and track roll forming machines and so on.