Floor Decking Forming Machine is a machine that processes metal sheets into specific cross-sectional shapes, mainly used for producing floor support plates. Floor slab is a commonly used building material in modern architecture, mainly used to replace traditional formwork. It has the characteristics of light weight, high strength, large load-bearing capacity, and good seismic resistance, and is widely used in high-rise buildings, bridges, tunnels, industrial plants, and other fields.

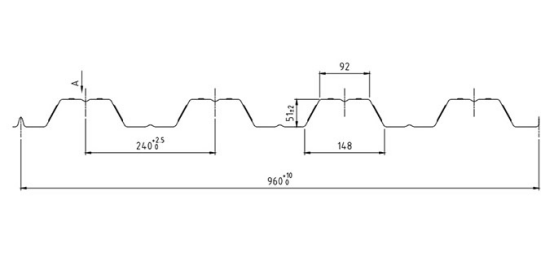

The profile drawing:

The pictures for the finished product:

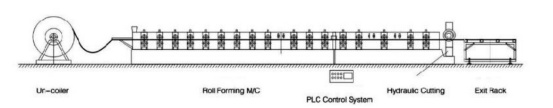

Production process:

Uncoiler-Feeding material into machine→Roll forming→hydraulic cutting→ Products receiving.

Packing list of the Floor Decking Forming Machine:

| No. | Name | Quantity |

| 1 | Manual/hydraulic Decoiler | 1 set |

| 2 | Main roll former | 1 set |

| 3 | Control system | 1 set |

| 4 | Hydraulic system | 1 set |

| 5 | Product Run-out table | 1 set |

The technical specifications of the Floor Decking Forming Machine:

| Item | Name | Specifications |

| 1 | Raw material | GI&PPGI |

| 2 | Raw material thickness | 0.7-1.5mm |

| 3 | Decoiler | 5T |

| 4 | Felt device | Available |

| 5 | Roller station | 28stations |

| 6 | Roller material | 45# steel |

| 7 | Shaft diameter | 85mm |

| 8 | Shaft material | 45# steel |

| 9 | Transmission | By double chains |

| 10 | Motor power | 5.5kw |

| 11 | Machine frame | 400H steel |

| 12 | Cutting type | Hydraulic cutting |

| 13 | Hydraulic power | 5.5kw |

| 14 | Cutting blade material | Cr12 quenched |

| 15 | Cutting tolerance | +/1mm |

| 16 | Control system | Delta/ Siemens PLC |

The function of the Floor Decking Forming Machine:

1. Efficiency:

The floor decking forming machine can efficiently process metal sheets into floor support plates with specific cross-sectional shapes through advanced roll forming technology and precise mechanical structure design. Its production process is stable and efficient, equipped with high-performance motors and automated control systems, greatly improving production efficiency.

2. Accuracy:

The floor support plate adopts precise cold bending forming technology to ensure that the produced floor support plate has the characteristics of light weight, high strength, and strong bearing capacity. Its design takes into account the actual needs of users, with simple and convenient parameter settings that can be adjusted according to different specifications and thickness requirements, ensuring the accuracy and quality of the product.

3. Durability:

Thefloor decking forming machine usually uses high-quality materials and advanced manufacturing processes to ensure the stability and service life of the machine.