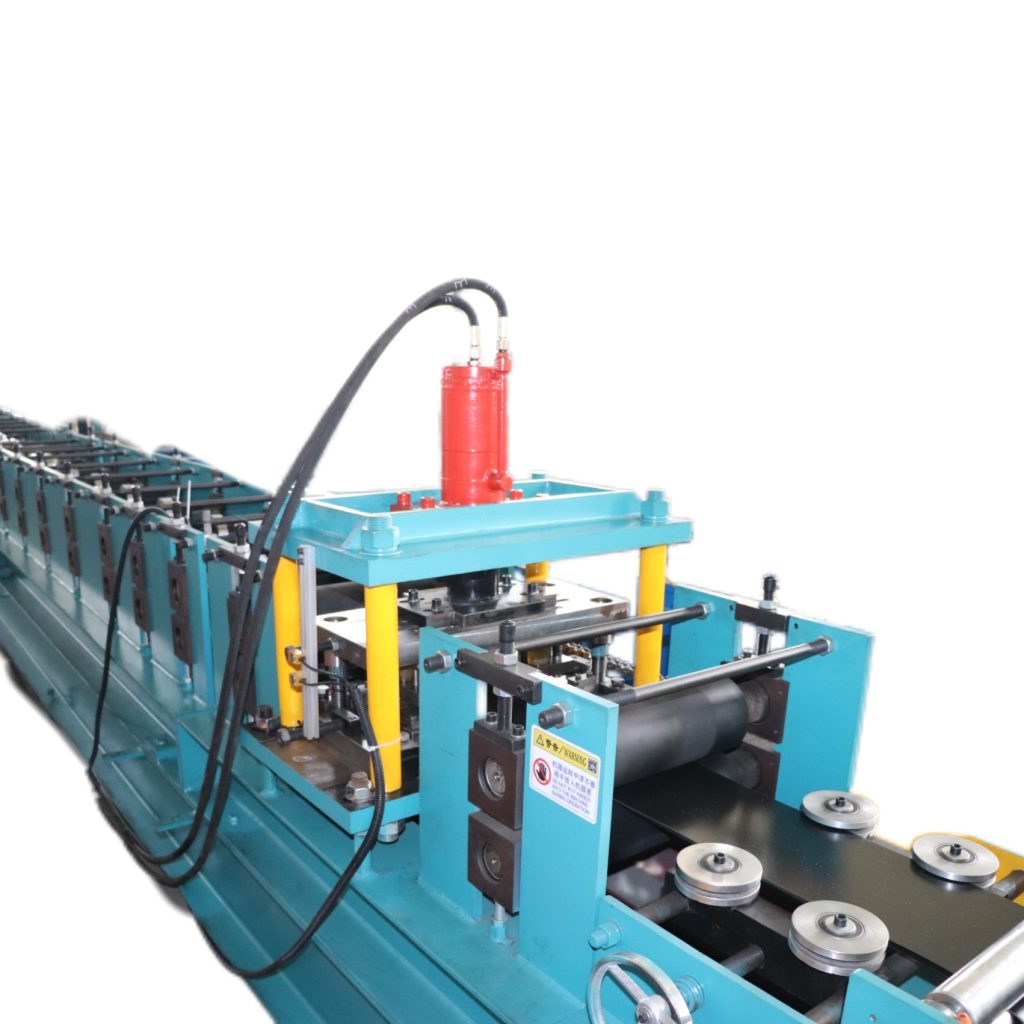

Rain Gutter Roofing Downspout Roll Form Machine

The Rain Gutter Roofing Downspout Roll Form Machine is widely used in building construction projects, especially in buildings that require drainage systems. The products produced by it have the characteristics of not easily aging, long service life, easy installation, and simple maintenance, which can significantly improve the overall image and drainage effect of the building.

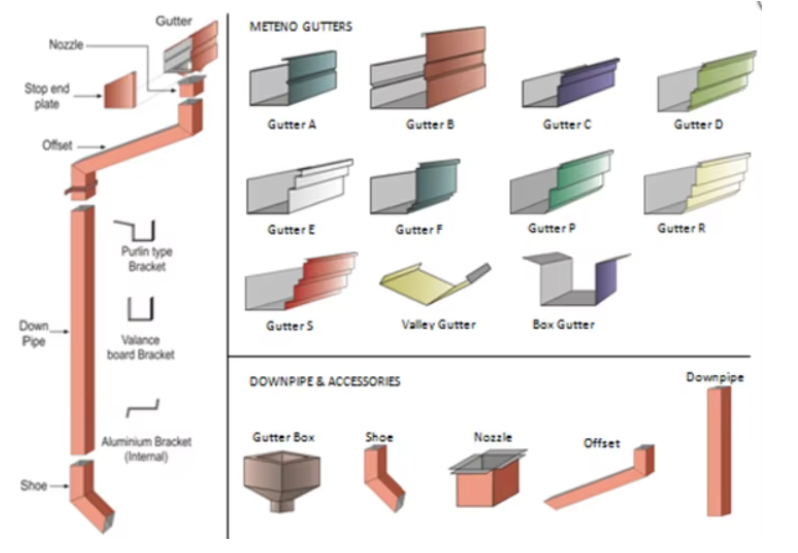

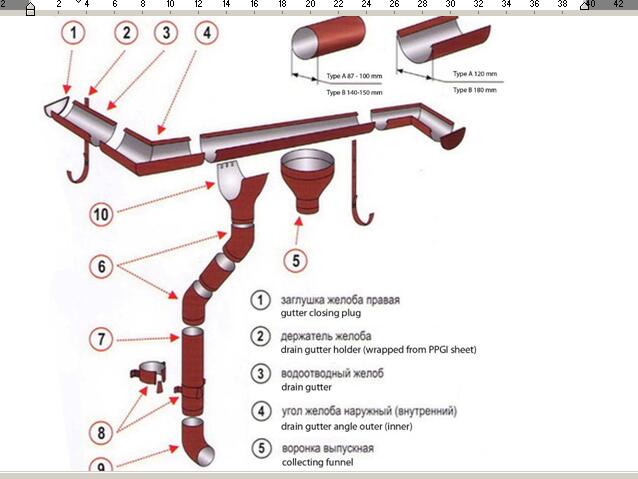

Finished product application:

There are many styles for you to choose from below:

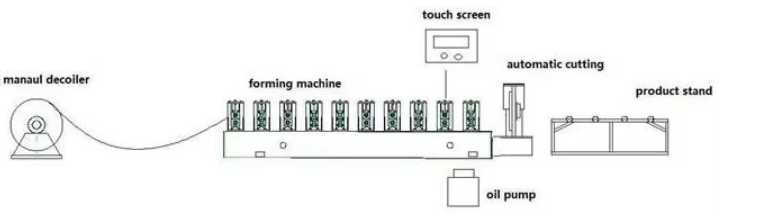

Operational Process:

Manual decoiler→Feeding material →roll forming→strengthening→Hydraulic cutting→product receiving table

Technical parameters:

|

1

|

Raw material

|

GI&PPGI

|

|

2

|

Weight of main part

|

2.5 t

|

|

3

|

Voltage

|

380 V/ 50 HZ 3 Phase (as customer’s request)

|

|

4

|

Roller fixer

|

Middle plate welded

|

|

5

|

Frame

|

350 H steel welded

|

|

6

|

Framme thickness

|

30 mm

|

|

7

|

Drive mode

|

Double Chain

|

|

8

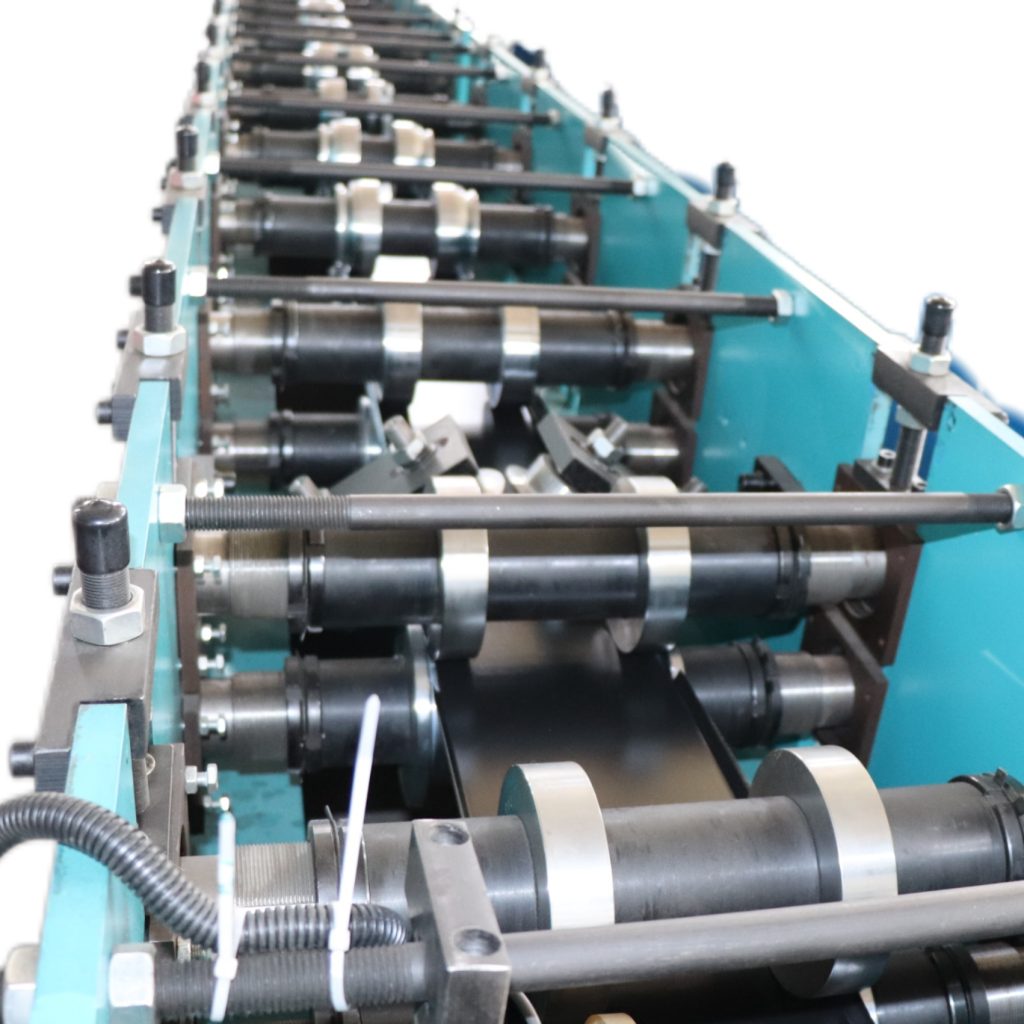

|

Material of rollers

|

45# steel, surface hard chromium plating

|

|

9

|

Material of shafts

|

45# steel

|

|

10

|

Diameter of shafts

|

Φ 75 mm

|

|

11

|

Number of rollers

|

20rollers

|

|

12

|

Main power

|

3 kw

|

Specific function:

1.Efficient installation:

The Rain Gutter Roofing Downspout Roll Form Machine can quickly and accurately install Rain Gutter and downspouts, significantly improving construction efficiency and reducing manual operation time and labor intensity.

2. Ensure smooth drainage:

By precise installation, it ensures that rainwater can flow smoothly, avoiding water accumulation and ensuring the drainage function of the building.

3. Enhance the aesthetic appeal of buildings:

The design of the Rain Gutter Roofing Downspout not only has drainage function, but also has a certain decorative effect, making the building appearance more beautiful and generous.