Video Description:

Double Layer Trapezoidal and Corrugated Roof Sheet Roll Forming Machine

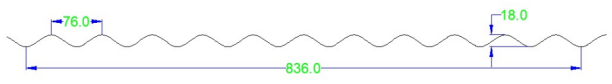

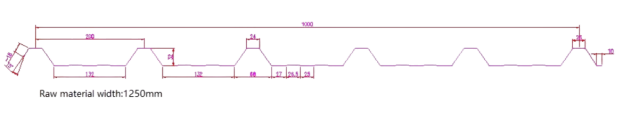

The Double Layer Trapezoidal and Corrugated Roof Sheet Roll Forming Machine significantly improves production efficiency and reduces production costs by simultaneously producing trapezoidal roof tiles and Corrugated roof tiles. And this design allows for the simultaneous production of two layers of tiles in a single workflow, significantly increasing productivity.

The advantages of this machine:

- Cost savings:

The double-layer structure design reduces the footprint of equipment and factory buildings, and the produced tiles can be used for building roofs and walls, saving building material costs. - Efficient production:

Double layered tiles can produce two different shapes and specifications of tiles simultaneously, greatly improving production efficiency and reducing labor costs.

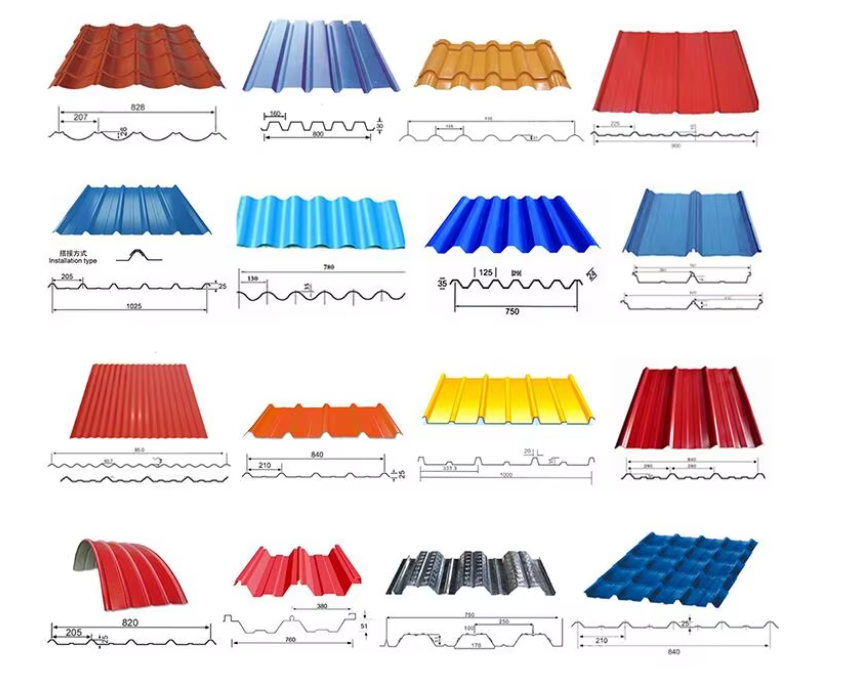

You can choose from other pattern designs that you want to customize here:

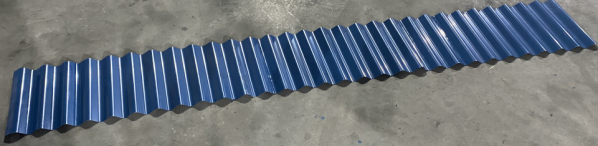

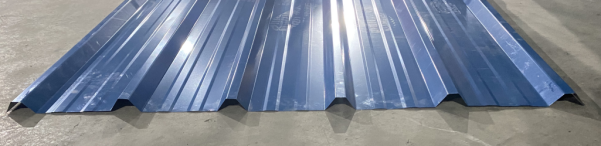

The pictures for the finished product:

Packing list of the Double Layer Trapezoidal and Corrugated Roof Sheet Roll Forming Machine:

| No. | Name | Quantity |

| 1 | Manual/hydraulic Decoiler | 1 set |

| 2 | Main roll former | 1 set |

| 3 | Control system | 1 set |

| 4 | Hydraulic system | 1 set |

| 5 | Product Run-out table | 1 set |

The technical specifications of the Double Layer Trapezoidal and Corrugated Roof Sheet Roll Forming Machine:

| Item | Name | Specifications |

| 1 | Raw material | GI&PPGI |

| 2 | Raw material thickness | 0.3-0.8mm |

| 3 | Decoiler | 5T |

| 4 | Felt device | Available |

| 5 | Roller station | 15stations |

| 6 | Roller material | 45# steel |

| 7 | Shaft diameter | 80mm |

| 8 | Shaft material | 45# steel |

| 9 | Transmission | By double chains |

| 10 | Motor power | 5.5kw |

| 11 | Machine frame | 350H steel |

| 12 | Cutting type | Hydraulic cutting |

| 13 | Hydraulic power | 5.5kw |

| 14 | Cutting blade material | Cr12 quenched |

| 15 | Cutting tolerance | +/1mm |

| 16 | Control system | Delta/ Siemens PLC |

Machine photos: