In the construction industry, Angle with punched holes Roll Forming Machine are widely used in the installation of structures such as walls and ceilings. Its excellent processing capability and molding accuracy make the building structure more stable and beautiful. Meanwhile, the Angle with punched holes Roll Forming Machine is also suitable for other fields that require metal punching and forming, such as mechanical manufacturing, automotive manufacturing, etc.

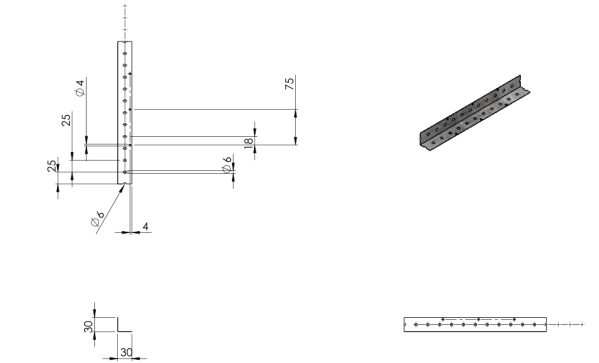

The profile drawing:

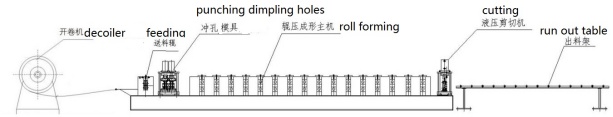

Production process:

Manual decoiler→ Feeding material into machine →Roll forming machine →Measure length →Hydraulic cutting →Finished Products

Packing list of the Angle with punched holes Roll Forming Machine:

| No. | Name | Quantity |

| 1 | Manual/hydraulic Decoiler | 1 set |

| 2 | Main roll former | 1 set |

| 3 | Control system | 1 set |

| 4 | Hydraulic system | 1 set |

| 5 | Product Run-out table | 1 set |

The technical specifications of the Angle with punched holes Roll Forming Machine:

| Item | Name | Specifications |

| 1 | Raw material | GI&PPGI |

| 2 | Raw material thickness | 0.45-0.8mm |

| 3 | Decoiler | 3T |

| 4 | Felt device | Available |

| 5 | Roller station | 12stations |

| 6 | Roller material | 45# steel |

| 7 | Shaft diameter | 40mm |

| 8 | Shaft material | 45# steel |

| 9 | Transmission | By Gear dual motor |

| 10 | Motor power | 3kw |

| 11 | Machine frame | Steel plate welded |

| 12 | Cutting type | Hydraulic cutting |

| 13 | Hydraulic power | 3kw |

| 14 | Cutting blade material | Cr12 quenched |

| 15 | Cutting tolerance | +/1mm |

| 16 | Control system | Delta/ Siemens PLC |

The function of the Angle with punched holes Roll Forming Machine:

1. Drilling processing:

The Angle with punched holes Roll Forming Machine can accurately punch various holes on materials such as angle steel to meet different connection and fixing requirements. This punching processing capability enables materials such as angle steel to be more easily connected to other components, forming a stable structural system.

2.Dragon bone forming:

In addition to drilling, the Angle with punched holes Roll Forming Machine can also shape angle steel and other materials into keel structures. Keel is a commonly used supporting structure in architecture, used to support components such as ceilings and walls. The Angle with punched holes Roll Forming Machine can ensure that the size and shape of the keel meet the design requirements through precise forming technology, thereby improving the stability and safety of the building structure.

3.Improve production efficiency:

The Angle with punched holes Roll Forming Machine adopts automated operation, precise control by computer, combined with automatic feeding and cutting functions, which can greatly improve production efficiency. Compared to traditional manual operations, Angle with punched holes Roll Forming Machine can complete punching and forming tasks faster, reducing labor and time costs.

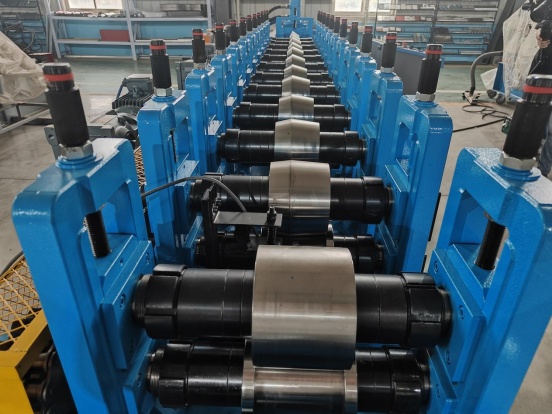

Some details of the Angle with punched holes Roll Forming Machine:

Our company Cangzhou Zhongtuo Roll Forming Machinery Co.,Ltd and Cangzhou Zhongtuo Internation Trade Co.,Ltd is the professional manfacture for the Roll forming machines,especially Roof and wall sheet roll forming machine, floor deck roll forming machines, CZ Purlin roll forming machines,Floor Decking Forming Machine light gauge drywall stud and track roll forming machines and so on.We look forward to working with you.