Metal steel construction material is becoming increasingly popular in modern constructions these days. Among roofing products, the standing seam panel holds an important position. The Bemo panel is one of the popular ones in markets such as those in India, Saudi Arabia, and the UAE.

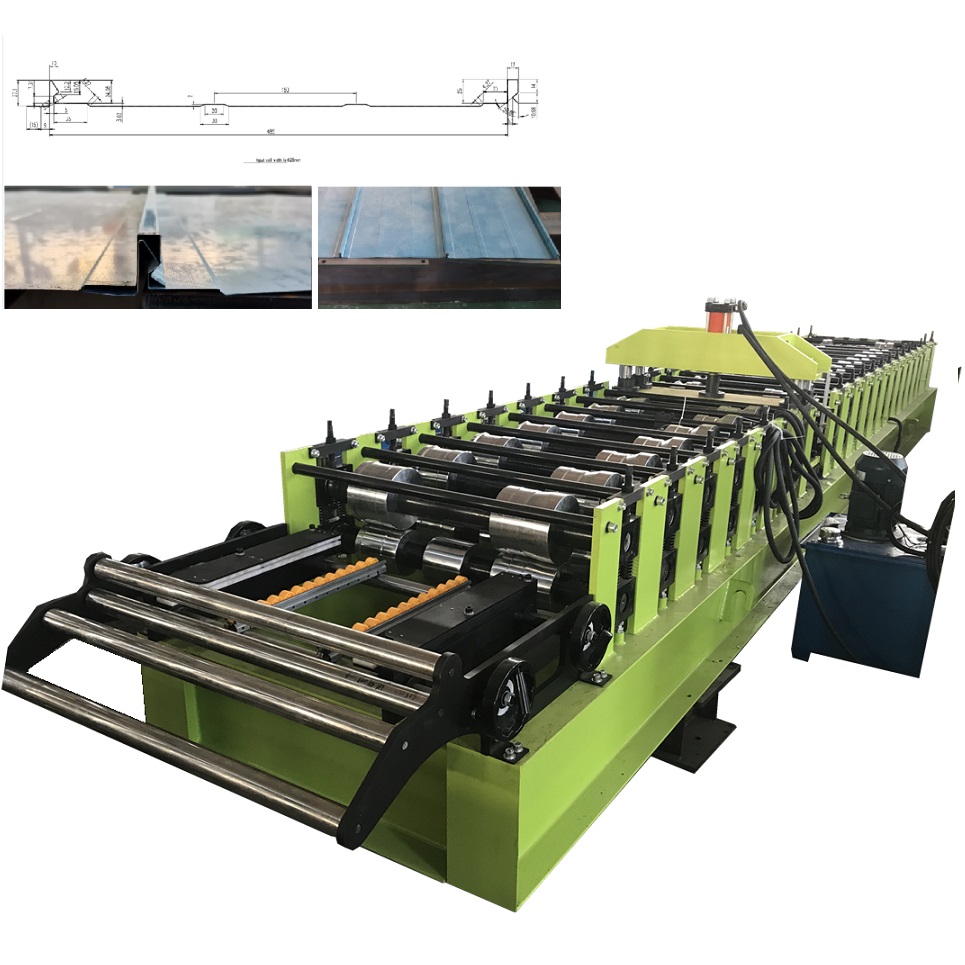

The Bemo panel standing seam panel roll forming machine consists of three parts, namely the main roll forming machine, the oblique slitting machine, and the double – side curving machine. This machine is capable of producing straight panels, tapered panels, as well as concave and convex panels, thus fulfilling the diverse requirements of different customized.

Bemo panel standing seam panel roll forming machine:

Main Parameters of roll forming machine:

| Forming stations | 13 rows |

| Forming speed | 25m/min(without cutting) |

| Voltage | 380V/50HZ/3P(Customized) |

| Main motor | 5.5KW*2 |

| Hydraulic motor | 2.2KW |

| Cutting type | hydraulic post cutting |

| Side rollers | Can make tapered panel with different width |

| Control type | PLC control |

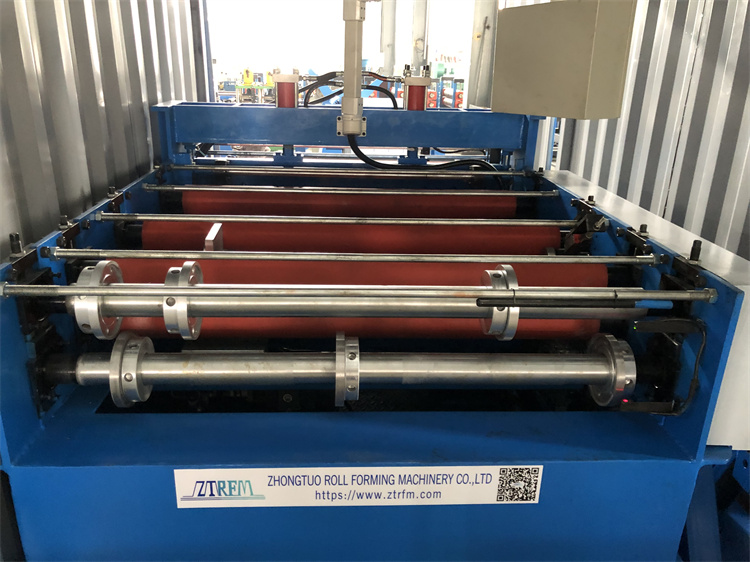

Oblique slitting machine

Double side curving machine

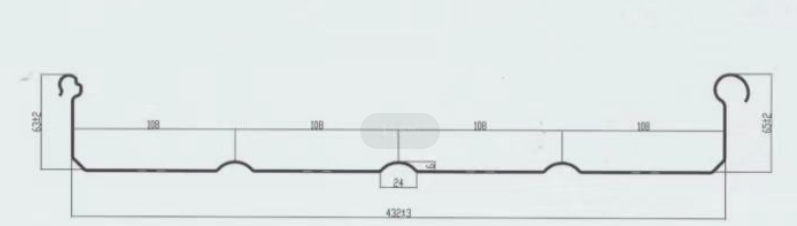

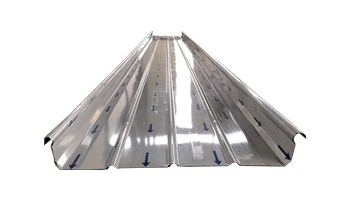

These are some application picture of the Bemo panel for your reference:

Recommend related machine: