Color steel metal roof panel sheet tile making cold roll forming machine is able to make the metal roofing sheets in batch and fully automatically. The raw material could be metal, aluminum, PPGI or other metals. The machine working speed can reach 25 meter per minute.

It can produce the metal roofing sheets. The inverter controls the motor speed, the PLC system controls length and quantity automatically, therefore, the machine achieves a continuous automatic production, which is the ideal equipment for cold roll forming industry.

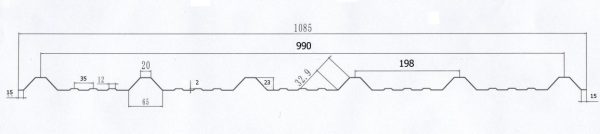

Take the following Color steel metal roof panel sheet drawing profile for example to show you how the machine is designed:

Color steel metal roof panel sheet tile making machine:

Main parmeters of the Color steel metal roof panel sheet tile making cold roll forming machine:

Features of this Color steel metal roof panel sheet tile making cold roll forming machine

| 1 | Length of the main part | 11500 х 1650 х 1450 mm |

| 2 | Weight of main part | 6 Ton |

| 3 | Voltage | 380 V/ 50 HZ 3 Phase (as customer’s request) |

| 4 | Roller fixer | Middle plate welded |

| 5 | Frame | 400 H steel welded |

| 6 | Frame thickness | 20mm thicker to be very strong |

| 7 | Drive mode | Chain of 1.25mm |

| 8 | Material of rollers | 45# steel, surface hard chromium plating. |

| 9 | Material of shafts | 45# steel |

| 10 | Diameter of shafts | Φ 80 mm |

| 11 | Number of rollers | 16 rollers |

| 14 | Main power | 15 kw |

- All the bolt and nuts we will do the chroming processing. It is good

- All the rollers are made chroming and all the spacer too.

- The entireframe, we use whole plate for more steady.

- Portable PLC operation, it is easy to operate.

- Double chain as transmission.