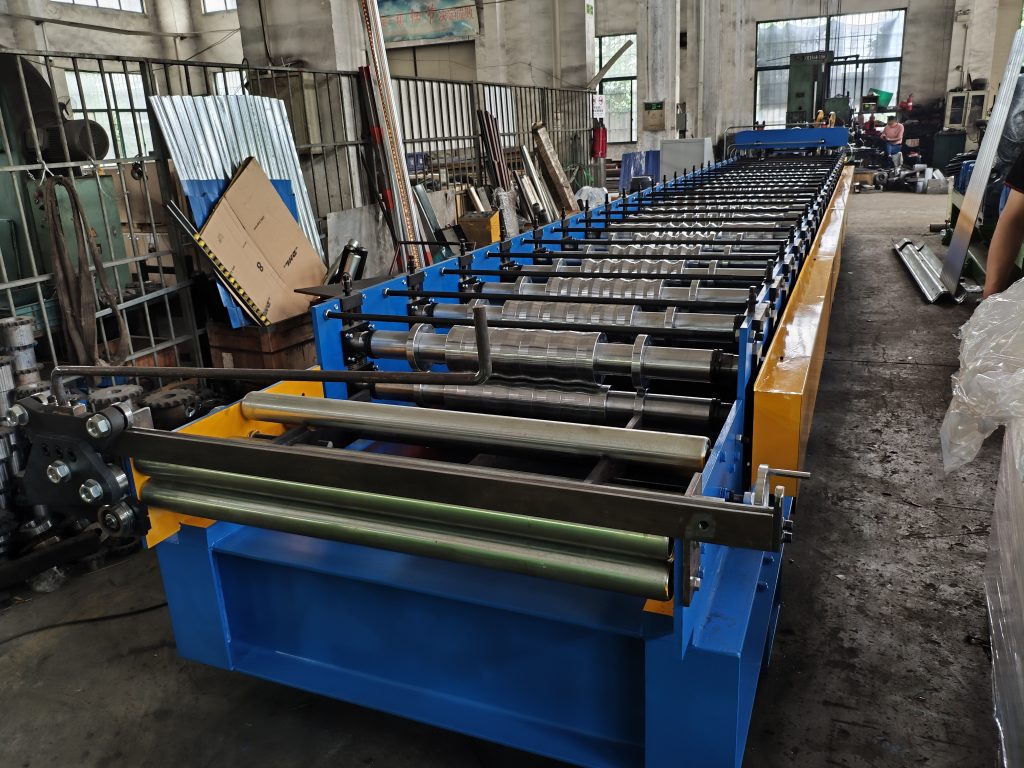

The main function of the Corrugated Roofing Sheet Roll Forming Machine is to manufacture curved roof panels. This machine uses pressure forming technology to press raw materials into roof panels with specific curvature, which is widely used in the construction industry to improve production efficiency and ensure the accuracy and quality of roof panels.

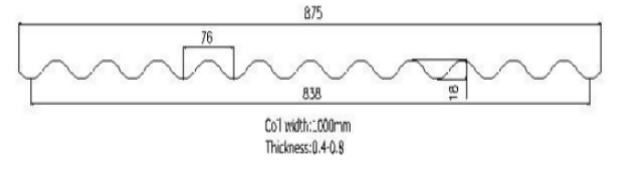

The profile drawing:

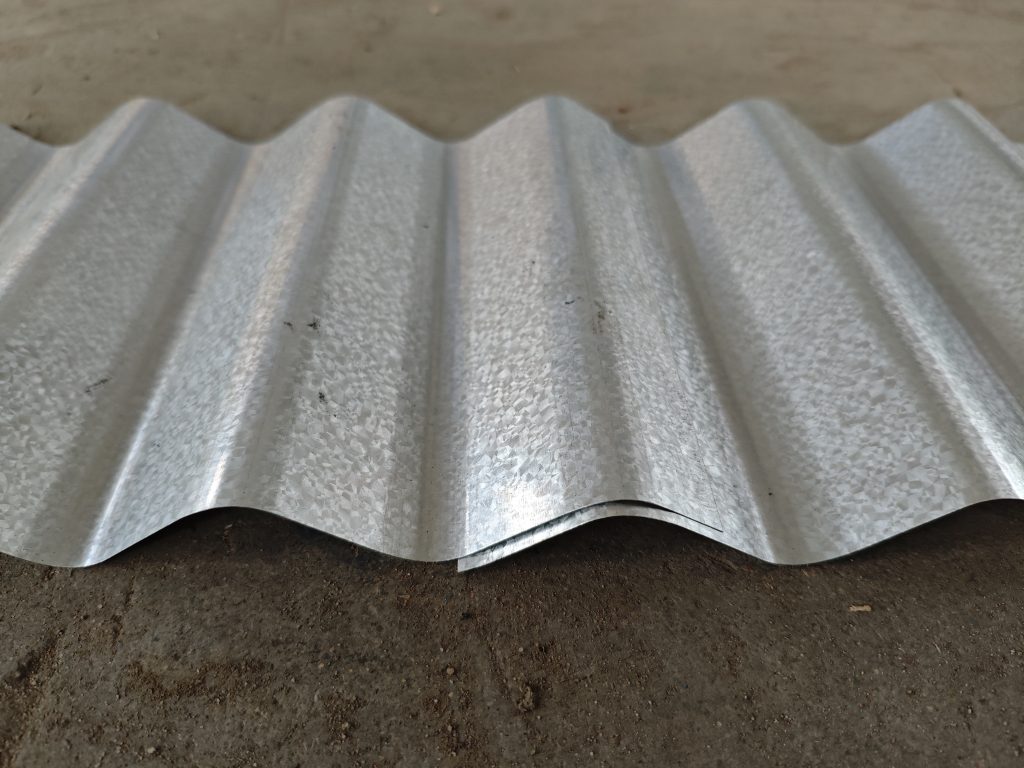

The pictures for the finished product:

Packing list of the Corrugated Roofing Sheet Roll Forming Machine :

| No. | Name | Quantity |

| 1 | Manual/hydraulic Decoiler | 1 set |

| 2 | Main roll former | 1 set |

| 3 | Control system | 1 set |

| 4 | Hydraulic system | 1 set |

| 5 | Product Run-out table | 1 set |

The technical specifications of the Corrugated Roofing Sheet Roll Forming Machine :

| Item | Name | Specifications |

| 1 | Raw material | Galvanized steel,Q235 |

| 2 | Raw material thickness | 0.18-0.28mm |

| 3 | Decoiler | 5T |

| 4 | Felt device | Available |

| 5 | Roller station | 24stations |

| 6 | Roller material | High grade 45# steel,chromed treatment |

| 7 | Shaft diameter | 80mm |

| 8 | Shaft material | High grade 45#,Tempering treatment |

| 9 | Transmission | By double chains |

| 10 | Motor power | 7.5kw |

| 11 | Machine frame | 400mm H beam structure |

| 12 | Cutting type | Hydraulic cutting |

| 13 | Hydraulic power | 5.5kw |

| 14 | Cutting blade material | Gcr12 quenched treatment |

| 15 | Cutting tolerance | +/1mm |

| 16 | Control system | Delta/ Siemens PLC |

The function of the Corrugated Roofing Sheet Roll Forming Machine :

1.Efficient production:

High frequency technology has the advantages of fast heating speed, uniform heating, effective energy saving, and precise process control, which can significantly improve production efficiency and quality. The high-frequency bending wood press adopts high-frequency low-temperature hot pressing technology, which can ensure that the wood does not crack and the adhesive curing strength is high.

2. Stable quality:

High frequency technology can uniformly and quickly heat the glue between the boards, while using a press for flexible pressing to ensure stable product quality and avoid quality problems.

3.Energy conservation and environmental protection:

High frequency technology can effectively save energy consumption, reduce environmental impact, and meet the energy-saving and environmental protection requirements of modern buildings.

4.Wide applicability:

High frequency technology is applicable to various materials, including multi-layer veneer, density board, etc., and can meet the needs of different materials.