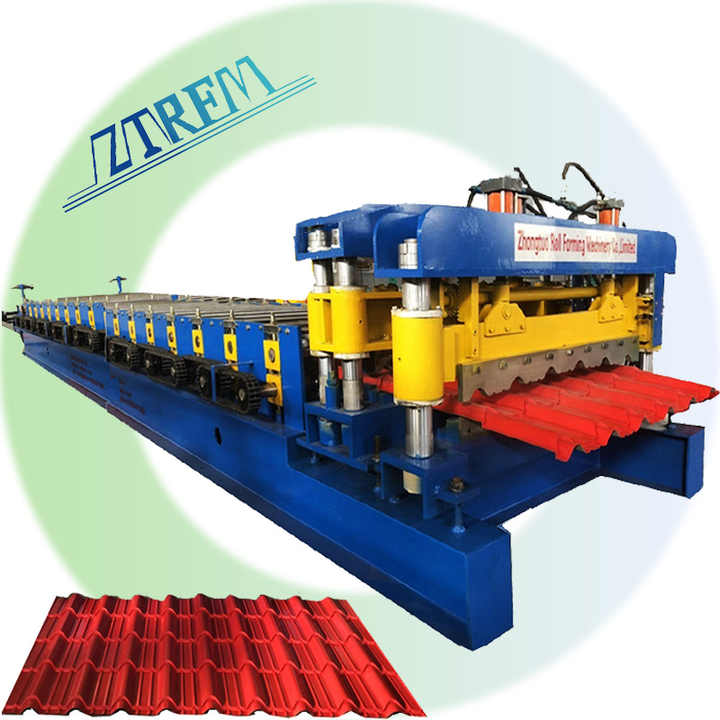

Corrugated Sheet Roll Former Machine is a specialized equipment that turns flat metal sheets into corrugated ones. It features a stable frame and a precisely designed set of rollers. A power system, usually an electric motor, drives the rollers to shape the metal. This machine is known for its high-precision forming ability, enabling it to produce corrugated sheets with accurate shapes and dimensions. It can work with various types of metal materials and offers a certain level of production efficiency, meeting the demands of different industries and construction projects.

Our company —CANGZHOU ZHONGTUO COLD ROLL FORMING MACHINERY CO, LTD,We have many years of experience in cold roll forming equipment. If you need rolling forming machine, you can consult us.

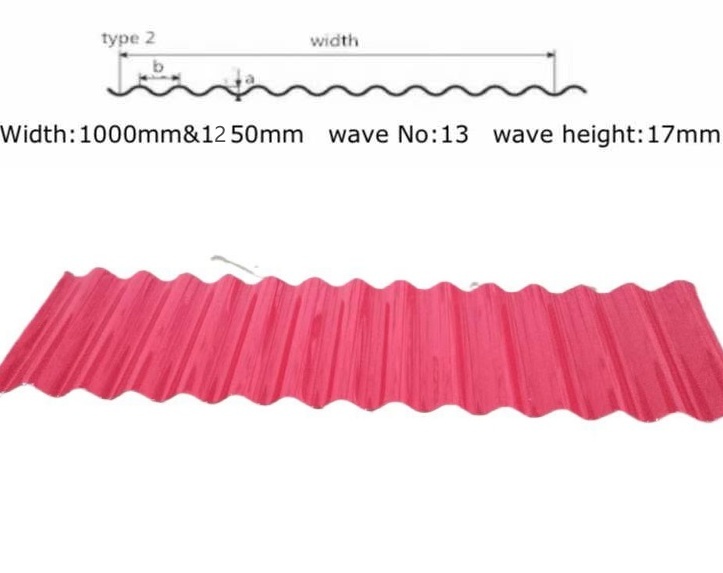

Corrugated Sheet Roll Former Machine

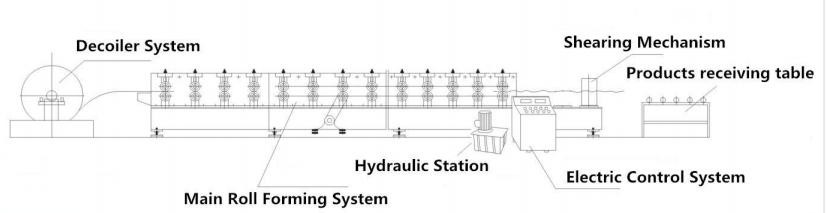

Corrugated Sheet Roll Former Machine Working Flow:

Basic information of Corrugated Sheet Roll Former Machine:

1.decoiler·

| Capacity | 5ton |

| Coil diameter | 450-550mm adjustable |

| Coil width | Max1350mm |

| Un-powered | manually control steel coil inner bore shrinkage and stop |

- Manual pre-cutter

Pre-cutter is suitable for frequent replacement of steel coil equipment,cutting steel coil in advance for easy replacement and reducing the wast of steel coil.

3.Main forming machine of Corrugated Sheet Roll Former Machine

| Main frame | 400mm H beam structure |

| Forming station | 24 stations |

| Roller material | High grade 45# |

| Shaft material | High grade 45#,Tempering treatment prevent deformed and improve the hardness |

| Shaft diameter | 80mm,solid |

| Motor power | 7.5kw |

| Speed | 0-20m/min |

| Transmission | chain transmission |

4.Control system of Corrugated Sheet Roll Former Machine

| Frequency converter | Delta |

| Screen | touch screen |

| PLC brand | Delta |

| Language | Chinese and English |

| Encoder | Omron |

| Feature | The control system support multi orders input ,it can match different production needs |

| Function | Cutting length control,cutting quantity control,and speed control |

5.Hydraulic cutting device

| Blade material | Gcr12 quenched treatment |

| Length tolerance | ±1mm |

| Hydraulic power | 5.5kw |

| Cutting feature | Steady and safe working condition and low sounds |

| Oil tube and wires connection | All the tubes and wires will be marked by the numbers or letters,so that it will be easy to connect for the new |

Related machine