Adhering to the industry standards and norms for qualitative production, we have successfully attained the name of reliable entity to offer an optimum quality range of Corrugated Sheet Roll Forming Machine. This machine is available in various technical specifications as per the requirements of our valuable clients. The provided machine is widely acknowledged by our esteemed clients owing to its long functional life and smooth operations. Furthermore, we provide this machine to our clients at most reasonable price.

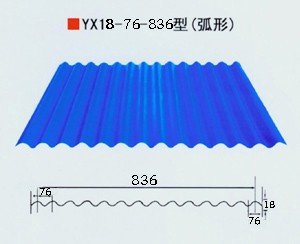

Profile drawing for reference,and we can also design the machine as your request.

Components of the whole production line:

| No. | Name | Quantity |

| 1 | Manual/hydraulic Decoiler | 1 set |

| 2 | Main roll former | 1 set |

| 3 | Control system | 1 set |

| 4 | Hydraulic system | 1 set |

| 5 | Product table | 2 sets |

Technical specifications of the whole production line:

Item | Name | Specifications |

1 | Decoiler | 1.Capacity:5 tons 2.Coil width:1250mm 3.Coil inner diameter:450-550mm 4.With manual braking system |

2 | Main roll former | 1.Roller station:18 station(according to profile drawing) 2.Roller material:Cr 12 with quenched treatment 3.Shaft diameter:80mm 4.Shaft material:45# steel with tempered 5.Transmission:by chain 6.Motor power:5.5kw 7.Machine frame:350H steel welded 8.Cutting type:Hydraulic cutting 9.Cutting blade material:Cr12 with quenched treatment 10.Cutting tolerance:+/-1mm |

3 | Control system | 1.Control system:PLC 2.PLC brand:Siemens 3.Touch screen brand:Siemens 4.Button brand:Schneider 5.Encoder brand:Omron 6.Low voltage apparatus:Schneider |

4 | Hydraulic system | 1.Power:5.5kw 2.With fan cooling device 3.Brand:Yuken |

5 | Product table | 1.Length:3 m 2.Type:up-powered |

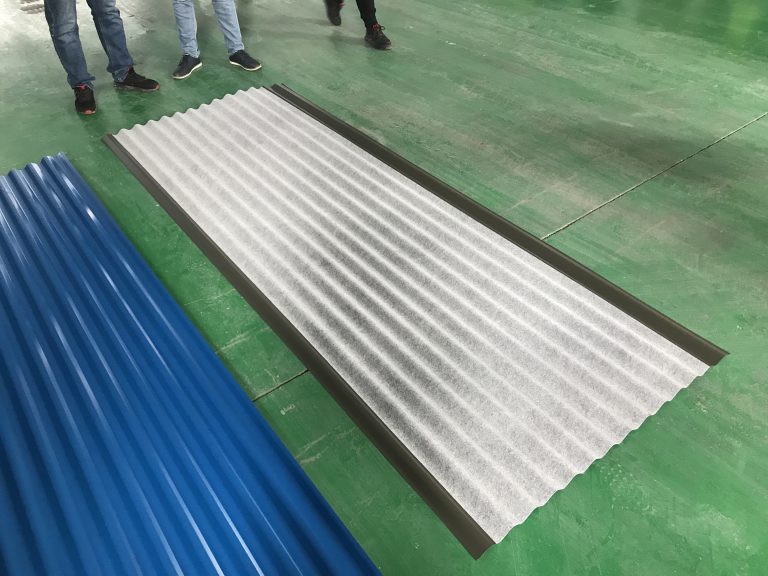

More detailed pictures for your reference: