The main function of the double layer roof tile machine is to efficiently and stably produce color steel tiles, which are widely used in the construction industry for roof and wall covering. The double layer roof tile machine can simultaneously produce two different types of color steel tiles, greatly improving production efficiency and saving space and costs.

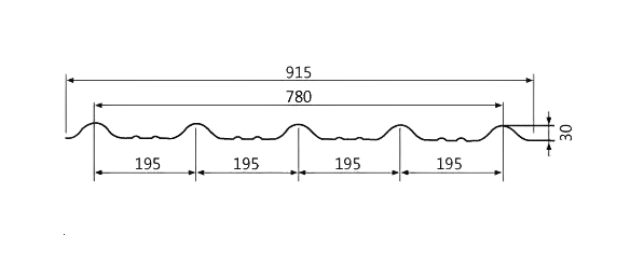

The profile drawing of the first layer machine:

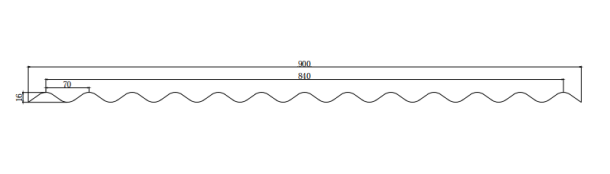

The profile drawing of the second layer machine:

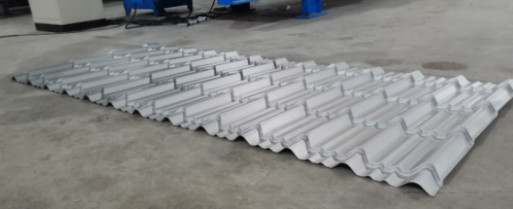

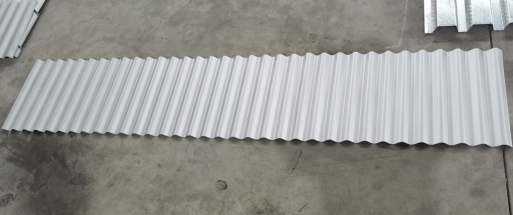

The pictures for the finished product:

Packing list of the Double layer roof tile machine:

| No. | Name | Quantity |

| 1 | Manual/hydraulic Decoiler | 1 set |

| 2 | Main roll former | 1 set |

| 3 | Control system | 1 set |

| 4 | Hydraulic system | 1 set |

| 5 | Product Run-out table | 1 set |

The technical specifications of the Double layer roof tile machine:

| Item | Name | Specifications |

| 1 | Raw material | GI&PPGI |

| 2 | Raw material thickness | 0.3-0.8mm |

| 3 | Decoiler | 5T |

| 4 | Felt device | Available |

| 5 | Roller station | 14+16stations |

| 6 | Roller material | 45# steel |

| 7 | Shaft diameter | 80mm |

| 8 | Shaft material | 45# steel |

| 9 | Transmission | By double chains |

| 10 | Motor power | 5.5kw |

| 11 | Machine frame | 350H steel |

| 12 | Cutting type | Hydraulic cutting |

| 13 | Hydraulic power | 5.5kw |

| 14 | Cutting blade material | Cr12 quenched |

| 15 | Cutting tolerance | +/1mm |

| 16 | Control system | Delta/ Siemens PLC |

The function of the Double layer roof tile machine:

1. Efficient production:

The double-layer roof tile machine can simultaneously produce two different shapes and specifications of tiles, greatly improving production efficiency and reducing labor costs. In addition, the double-layer design enables the equipment to save space and improve production efficiency.

2. High precision and consistency:

By adopting advanced numerical control technology and precise transmission system, the double-layer roof tile machine can ensure the accuracy and consistency of the product, guaranteeing the quality and appearance flatness of the product.

3. Multifunctionality:

This device can produce tiles of various shapes and specifications, such as single-layer, double-layer, angled, curved, etc., to meet the diverse needs of customers.

4. Environmental performance:

The double-layer roof tile machine adopts environmentally friendly materials, which are noise free and pollution-free, in line with modern environmental protection concepts.

Machine photos: