Downspout Pipe: a vertical pipe used to drain rainwater from a roof

2×3/3×4 Downspout Pipe Roll Forming Machine:

This machince can produce the downspout as the size which is requested by customer,and this machine also have the elbow machine to elbow the pipe.

2×3/3×4 Downspout Pipe Roll Forming Machine detailed technical specifications:

| Name | Specifications | |

| 1 | Decoiler | 3T Manual Decoiler |

| 2 | Machine frame | 350H steel,middle plate welded |

| 3 | Roller station | 19 stations with a series of vertical rollers |

| 4 | Roller material | 45# steel with quenched treatment |

| 5 | Shaft diameter | 70mm |

| 6 | Shaft material | 45# steel with tempered |

| 7 | Transmission | by chain |

| 8 | Motor power | 7.5kw |

| 9 | Machine frame | 350H steel welded |

| 10 | Cutting type | Hydraulic cutting |

| 11 | Hydraulic power | 4kw |

| 12 | Cutting blade material | Cr12 with quenched treatment |

| 13 | Cutting tolerance | +/-1mm |

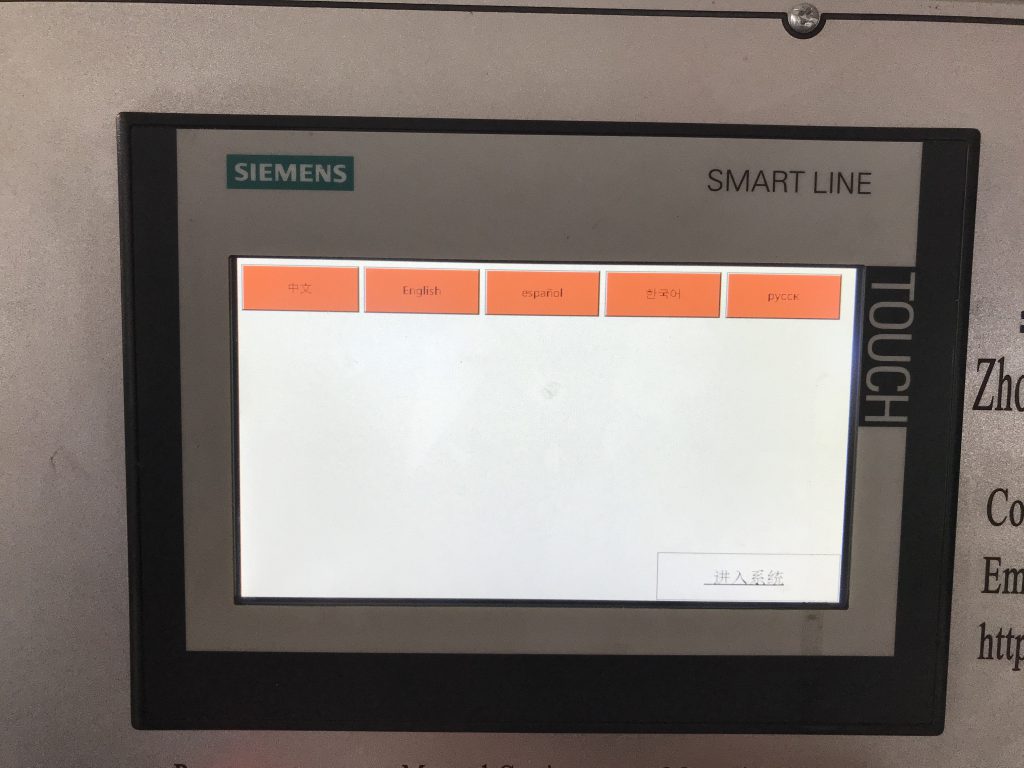

| 14 | Control system | PLC |

| 15 | Brand | PLC:Delta/Siemens/MitsubishiTouch screen:Delta/Siemens/MitsubishiEncoder:Omron |

| 16 | Voltage | 480V,60HZ,3PH or as customer’s request. |

The introduction for the component of the whole machine:

Part 1: Decoiler

- Capacity:3 tons

- Working type:Manual or automatic for option

Part 2:Roll Former with elbow machine

- 19 roller stations with a series of vertical rollers

- Main motor power:7.5kw

- Cutting,elbow and necking type:Hydraulic

- With hydraulic pre-cutter,can reduce waste material when change coils

Part 3:Control system

- Power:7.5kw

- Cooling system:by fan

Part 4:Control system