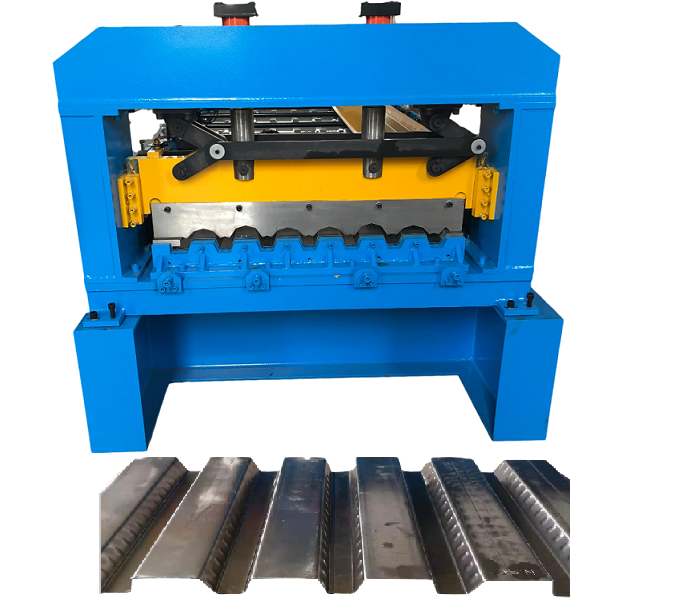

The floor decking roll forming machine remains an important piece of equipment specifically utilized for the production of floor decks. In the construction domain, the application of floor deck machines has significantly enhanced construction efficiency and reinforced the structural stability and safety of buildings. In high-rise buildings, it can not only save steel formwork but also reduce the load on the floor

The working flow of floor decking roll forming machine

Uncoiling → Feeding material into machine → roll forming → Products receiving table

The floor decking roll forming machine have theses advantage

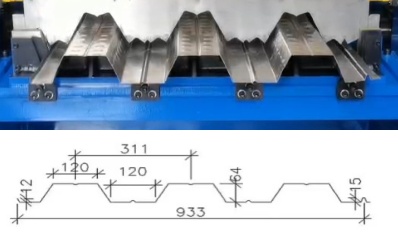

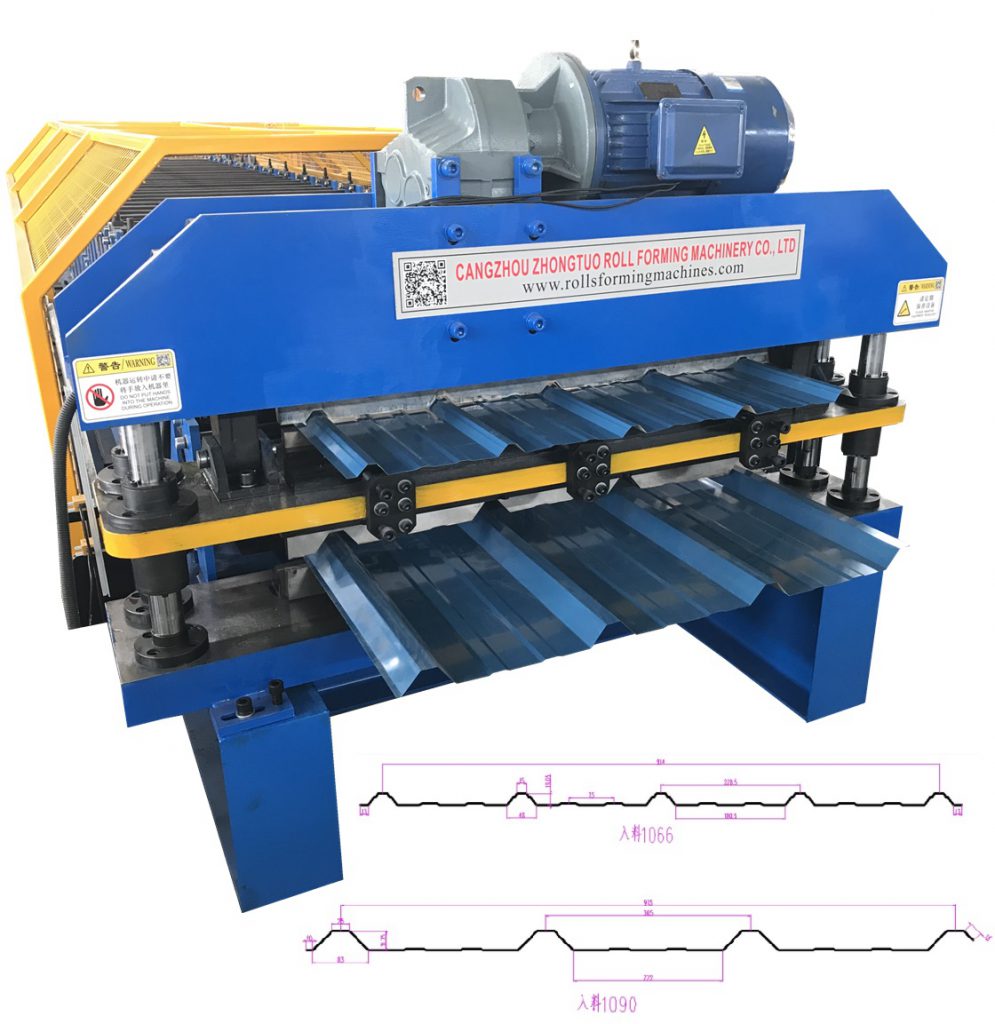

1.High-precision forming: The raw material can be accurately roll form into the shape of the floor deck that meets the customers’ requirements.

Thickness : 0.75-1.5mm the size of the product can be customized

2.Fully automatic:Automatic decoiler and stacker, according to the customer’s requirements.

3.roll forming machine

| Rolling station | 28 stations |

| Middle wall plate | 20mm thickness |

| Work speed | 0-25 m/min |

| Roller material | Cr15,with quenched treatment,surface is hard chromed |

| Shaft type | solid shaft |

| Shaft diameter | 90-100 mm |

| Machine basic frame | 400# H steel welded, Anti rusty treatment after welding |

| Transmission | By Chains with cover |

4.Hydraulic cutting system of floor decking roll forming machine

Driving method: By pillar type Cylinder

Hydraulic motor power: 5.5 kw

Cutter material: GB-Cr12

Cutting feature: Steady and safe working condition

5.PLC control system of floor decking roll forming machine

PLC brand: Siemens

Screen type: Touch screen, also have buttons on the panel

6.Guarantee and service

(1) Certification: Our machines have CE certification, etc. CE certification is the safety certification of the European Union and the license for products to enter the EU market.

If there are certification requirements in other countries, we can also apply according to customer requirements.

(2) Packing and transportation: The machine is fixed in the container, and the accessories are packed in wooden cases to protect the machine and accessories from damage during transportation.

(3) Provide good pre-sales and after-sales service, can send engineers to the customer’s factory to install the machine, train the workers.