The glazed tile machine is a specialized equipment used for producing glazed tiles. Glazed tiles are a traditional building material with characteristics such as waterproofing, fire resistance, corrosion resistance, and bright colors. They are commonly used for roof decoration in ancient buildings, garden landscapes, modern antique buildings, and other places. The glazed tile machine can efficiently manufacture various specifications and styles of glazed tiles through automated production processes, meeting the needs of the construction market.

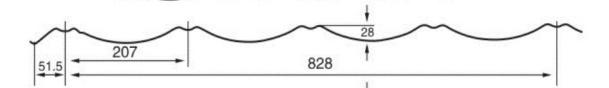

The profile drawing:

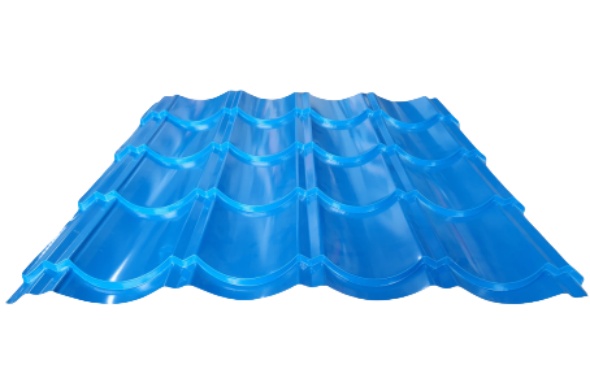

The pictures for the finished product:

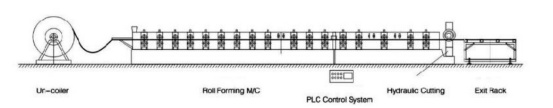

Production process:

Uncoiler-Feeding material into machine→Roll forming→hydraulic cutting→ Products receiving

Packing list of the Glazed tile machine :

| No. | Name | Quantity |

| 1 | Manual/hydraulic Decoiler | 1 set |

| 2 | Main roll former | 1 set |

| 3 | Control system | 1 set |

| 4 | Hydraulic system | 1 set |

| 5 | Product Run-out table | 1 set |

The technical specifications of the Glazed tile machine :

| Item | Name | Specifications |

| 1 | Raw material | GI&PPGI |

| 2 | Raw material thickness | 0.3—0.8mm |

| 3 | Decoiler | 5T |

| 4 | Felt device | Available |

| 5 | Roller station | 14stations |

| 6 | Roller material | 45# steel |

| 7 | Shaft diameter | 80mm |

| 8 | Shaft material | 45# steel |

| 9 | Transmission | By double chains |

| 10 | Motor power | 5.5kw |

| 11 | Machine frame | 350 H steel |

| 12 | Cutting type | Hydraulic cutting |

| 13 | Hydraulic power | 5.5kw |

| 14 | Cutting blade material | Cr12 quenched |

| 15 | Cutting tolerance | +/1mm |

| 16 | Control system | Delta/ Siemens PLC |

The function of the Glazed tile machine :

1.Efficient production:

Adopting advanced hydraulic systems and automated control systems, the production efficiency is high and can meet the needs of large-scale production.

2.High precision and high stability:

The cutting system of the glazed tile machine has high precision, flat cutting surface, good product quality, beautiful appearance, uniform color, and is not easily discolored.

3.Low maintenance cost:

The equipment has a high degree of automation, saving labor costs, while the maintenance and upkeep costs are relatively low.

4.Easy to operate:

The control system is easy to operate, the program runs stably and reliably, the cutting accuracy is high, and it meets the process requirements.