High Speed Flying Shear Corrugated Sheet Roll Forming Machine

High Speed Flying Shear Corrugated Sheet Roll Forming Machine is an advanced equipment specially used for processing metal corrugated sheets.

High Speed Flying Shear Corrugated Sheet Roll Forming Machine has the following outstanding advantages:

1. High-efficiency production capacity: It can form metal materials into arc-shaped metal tiles at a very fast speed. Compared with traditional equipment, it greatly shortens the production cycle and meets the needs of large-scale production.

2. Precision forming process: It can accurately shape the arc shape that meets the design standards, ensuring that the size and curvature of each metal tile are highly consistent. This makes the installed metal tiles look neat and beautiful, and have good waterproof performance.

3. High degree of automation: Equipped with an advanced automatic control system, the operator only needs to set the relevant parameters, and the machine can automatically complete a series of processing procedures, reducing the error and labor intensity of manual operation.

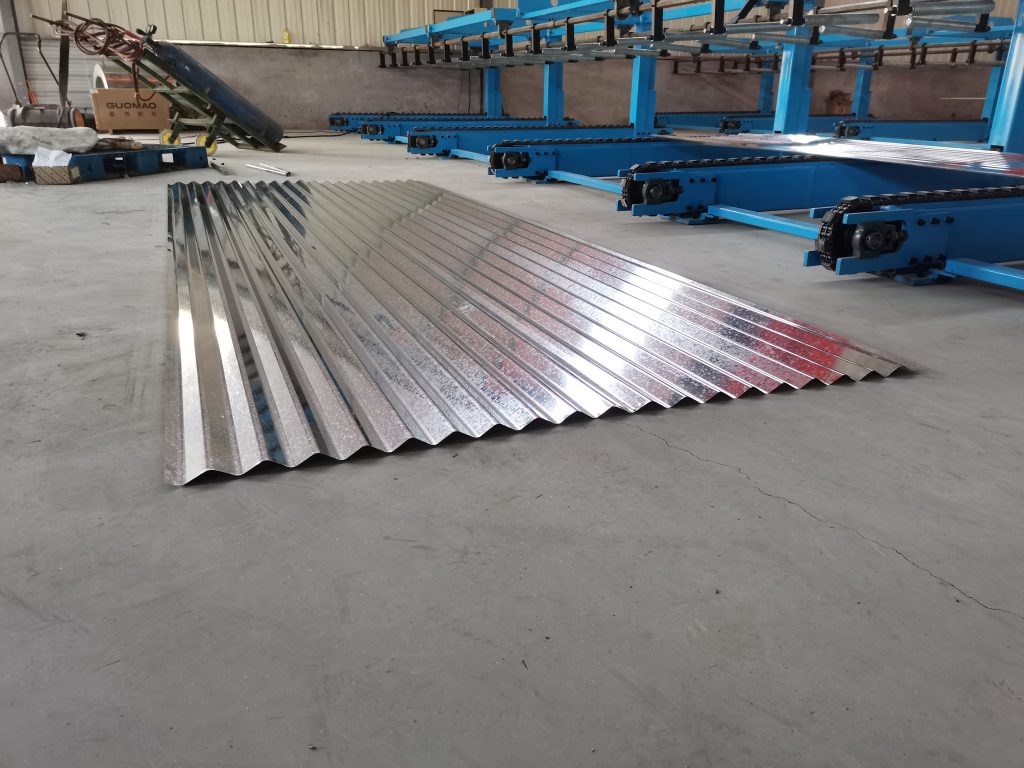

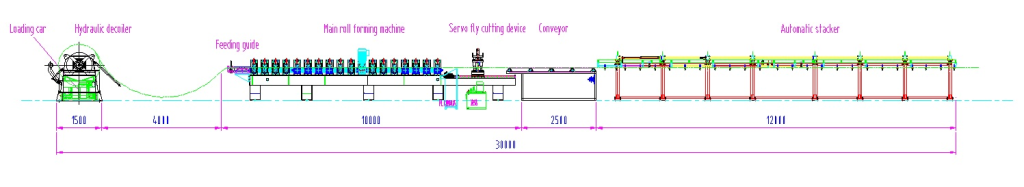

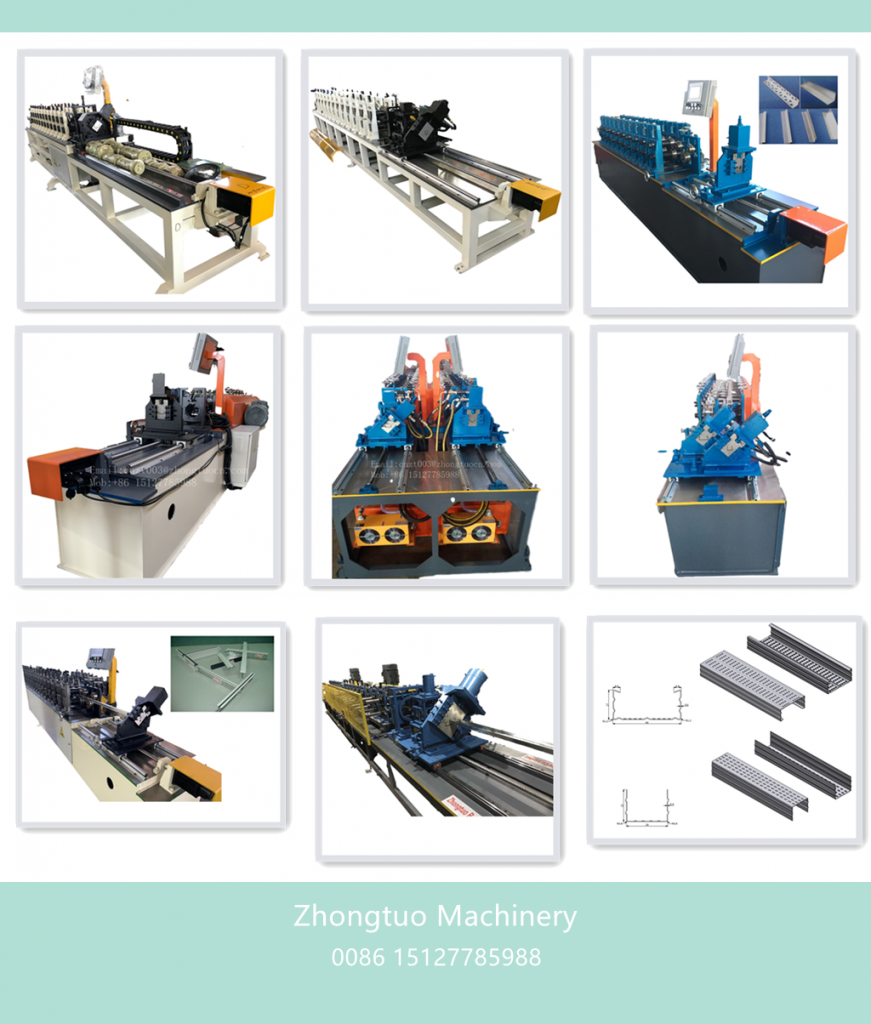

The pictures of the High Speed Flying Shear Corrugated Sheet Roll Forming Machine:

The introduction of the High Speed Flying Shear Corrugated Sheet Roll Forming Machine:

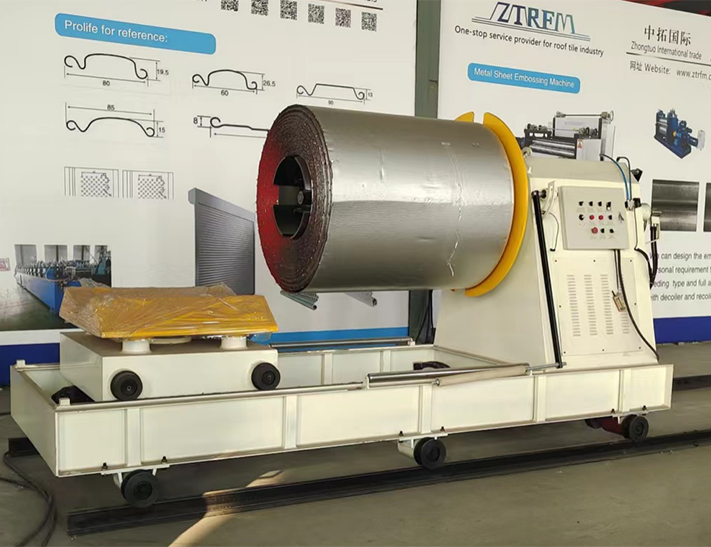

Part 1: Uncoiler

- Capacity: 5-10 tons as customer’s request

- Working type: Hydraulic expansion, motor drives forward and backward.

- Equipped with loading car

- Equipped with press arm to keep the coil from loosing

- Equipped with speed sensor to match with the whole production line’s speed.

Part 2: Main Roll Forming Machine

- Roll material: High grade 45# steel with quenched treatment, surface is chromed with the thickness of 0.08mm.

- Shaft diameter: 80mm, solid shaft.

- Machine frame: 500H steel welded, in the middle with diagonal frame support.

- Transmission: By gearbox

- Structure: Iron cast molding frame.

- Motor power: 15 kw

Part 3: Hydraulic flying shear device

- Feature: Servo motor drived flying shear, when cutting the roll former will not stop

- Working type: Hydraulic

- Hydraulic power: 11 kw, with accumulator, fan cooling

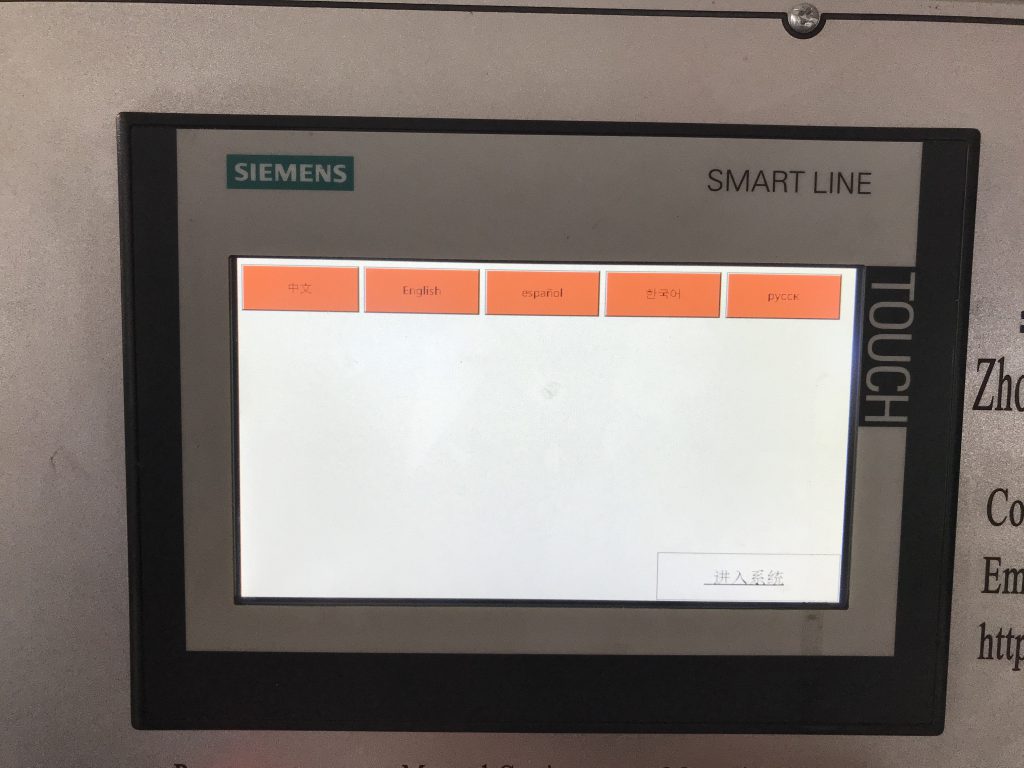

Part 4: Control system

- Control system: PLC

- Touch screen brand: Siemens / Delta / Mitsubish

- PLC brand: Siemens / Delta / Mitsubish

- Function: Control the length, quantity and batch, control the production line speed.

- Advantages: remote-control function

Part 5: Automatic stacker

- Length: 3-12 meters, support customization as customer’s request.

- Working type: receive the finished product automatically after cutting, and make them orderly and convey one batch out after production.

- Electric and pneumatic working.

The whole production line’s working video at customer’s factory and customer’s feednback for our machines:

Our company Cangzhou Zhongtuo Roll Forming Machinery Co.,Ltd and Cangzhou Zhongtuo Internation Trade Co.,Ltd is the professional manfacture for the Roll forming machines, especially Roof and wall sheet roll forming machine, floor deck roll forming machines, CZ Purlin roll forming machines, light gauge drywall stud and track roll forming machines and so on. We have exported a lot of machines to USA, Canada, Mexico, European countries and so on. We also support customization as customer’s request.