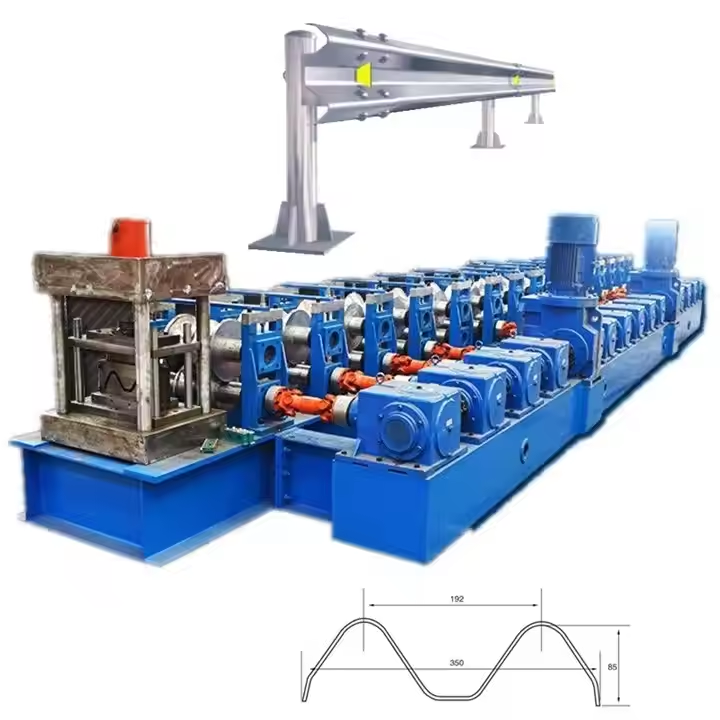

The Highway Guardrail Roll Forming Machine is mainly utilized for manufacturing the guard rails on roads. It has the functions of continuous uncoiling, feeding materials, punching holes, roll forming, punching logos and cutting to the required length. The entire production line adopts the PLC control system and the AC variable frequency speed adjustment, enabling it to operate fully automatically. This machine is indispensable equipment in both the steel structure industry and the road transportation industry. It uses two cassettes to produce two different profiles, specifically the two waves guardrail profile and the three waves guardrail profile.

Moreover, the machine can be customized according to the specific technical requirements put forward by customers.

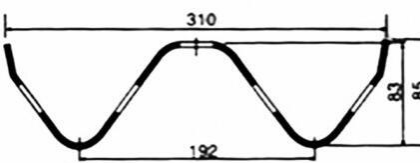

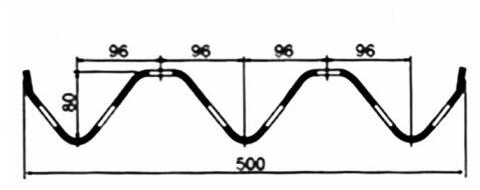

Customer profile drawing:

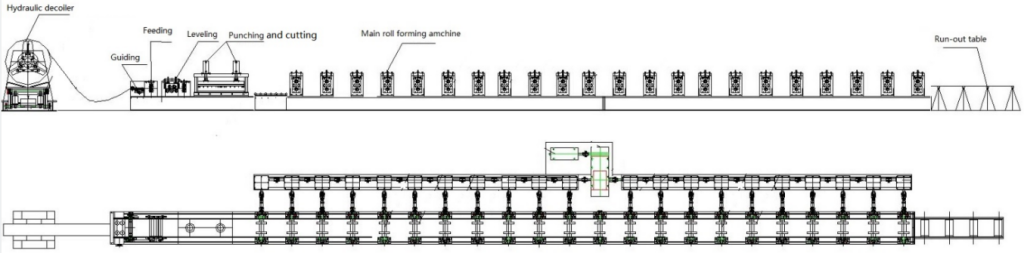

Working flow of Highway Guardrail Roll Forming Machine:

Technical of the whole line:

1.10 tons hydraulic decoiler

| Capacity | 10 tons |

| Coil diamete | 450-550mm adjustable |

| Coil width | max 800mm |

| Hydraulic powe | 4kw |

| Motor power | 7.5kw |

- Guiding & leveling device

| Roller diameter | 95mm |

| Material | 45# steel |

| Drive power | 5.5kw |

3.Main forming machine

| Rolling shaft material | 45# steel with quenched treatment |

| Shaft diameter | 100mm |

| Roller material | GB-Cr15 with heat treatment |

| Rolling station | 19station |

| Working speed | 6-10m/min |

| Transmission | By gearbox |

Recommend related machine: