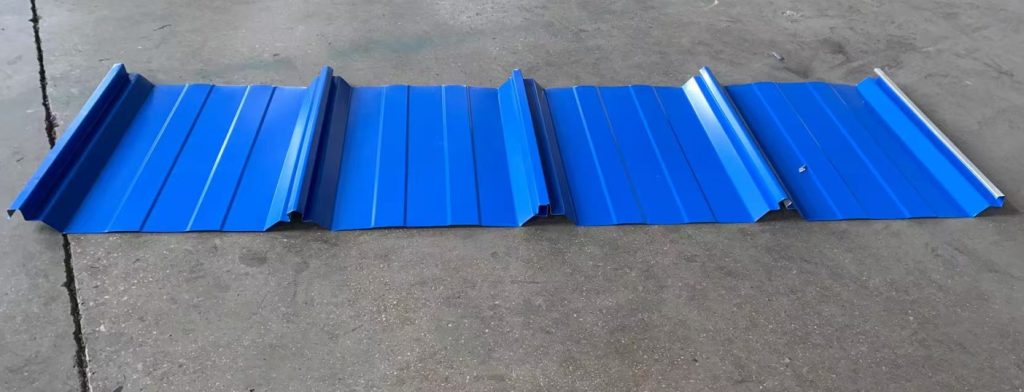

Metal Roofing Panel Making Standing Seam Forming Machine

Metal Roofing Panel Making Standing Seam Forming Machine used for producing vertical seam roof tiles, widely used in industrial and civil construction fields. The characteristic of this type of tile is that the tiles are connected by vertical seams, which enhances the stability and waterproof performance of the roof. The Metal Roofing Panel Making Standing Seam Forming Machine usually consists of parts such as feeding, forming, and post forming cutting, which can produce tiles with a smooth appearance, uniform paint patterns, and high strength.

Here is the operation video of our machine:

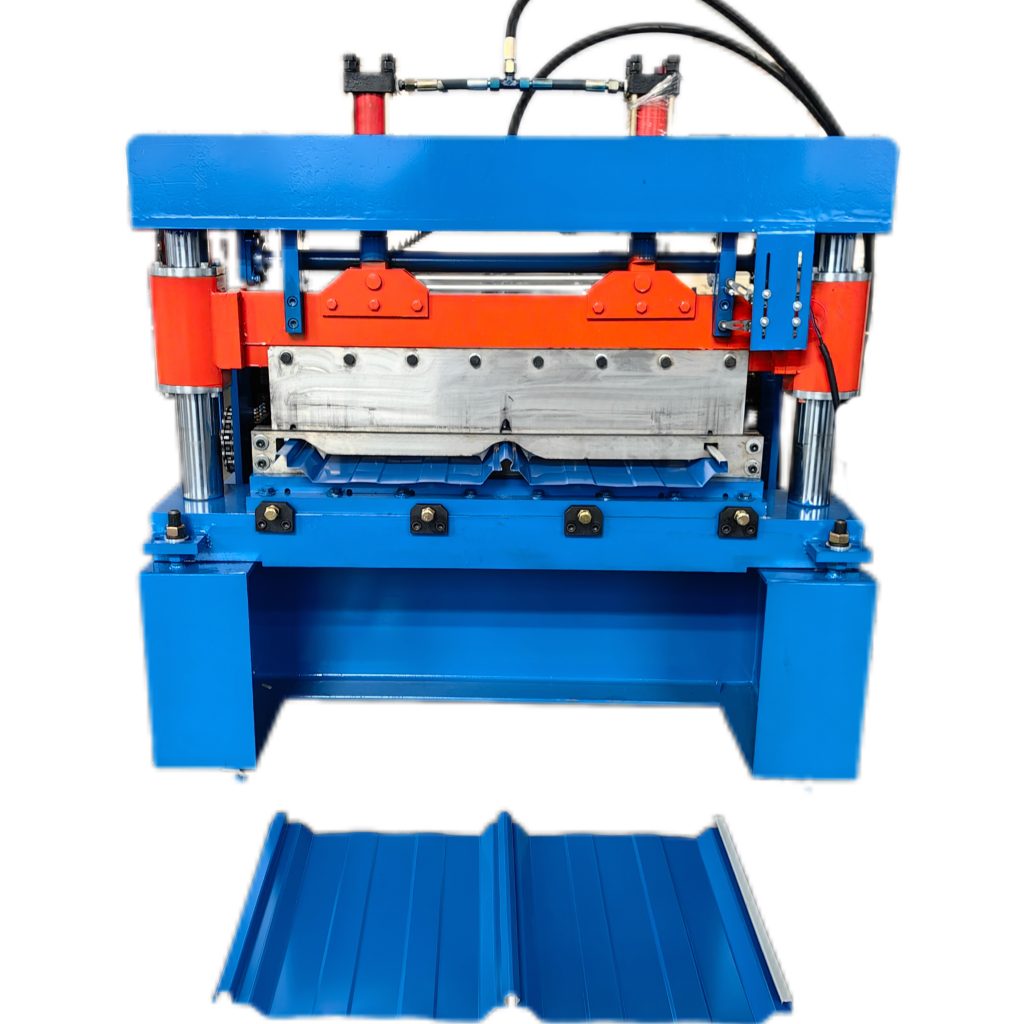

Here are photos of Metal Roofing Panel Making Standing Seam Forming Machine:

Product introduction:

Part 1: Hydraulic decoiler

1.Function:Supporting the coils and doing uncoiling.

2.Capacity:3 tons

3.Coil inner diameter:450-550 mm

4.Coil width:650mm

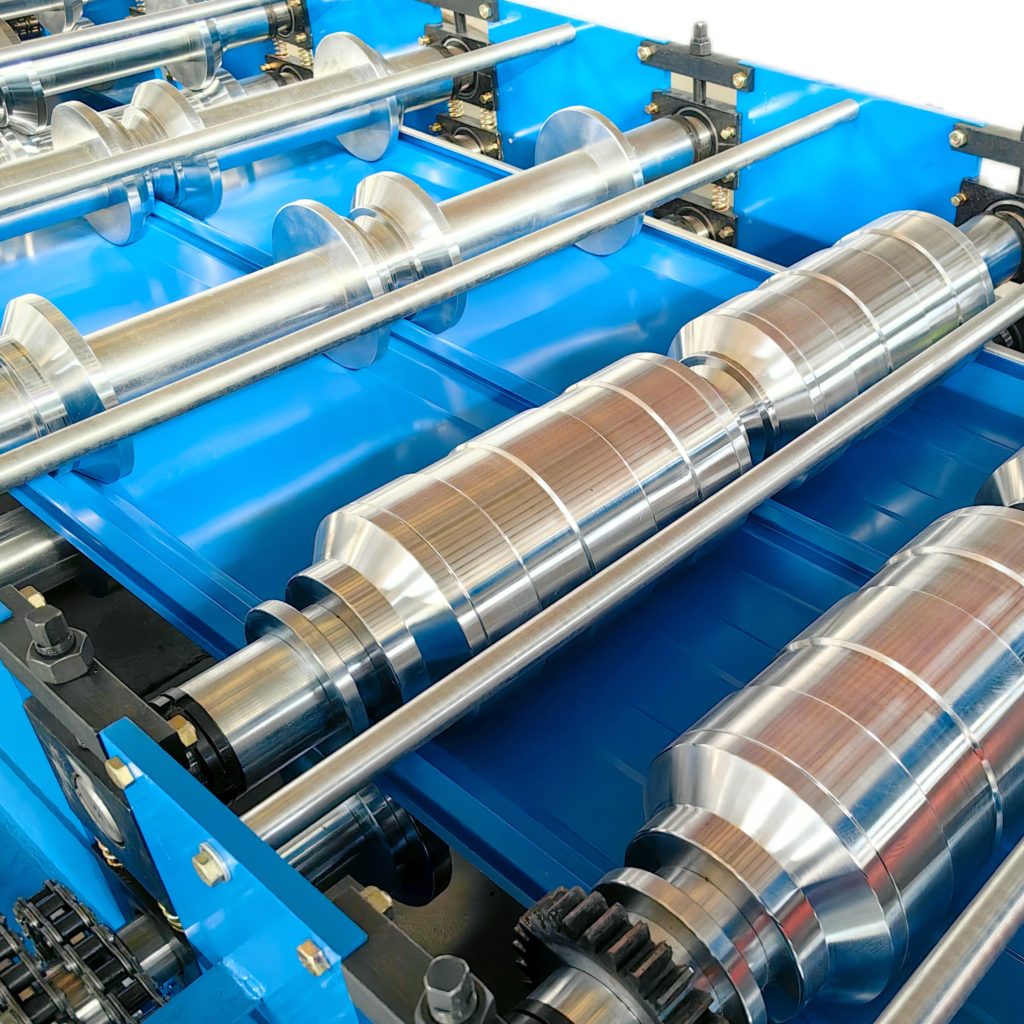

Part 2: Main roll forming machine

1.Shaft material:45# STEEL with quenched and tempering

2.Shaft diameter:70mm, solid shaft

3.Roller material:High grade 45# steel, surface chromed thickness 0.05mm

4.Roller station:20 stations

5.Work speed:About 0-15m/min

6.Machine body:350H steel welded

7.Bearing :Chinese famous brand Harbin

8.Work power:5.5 kw

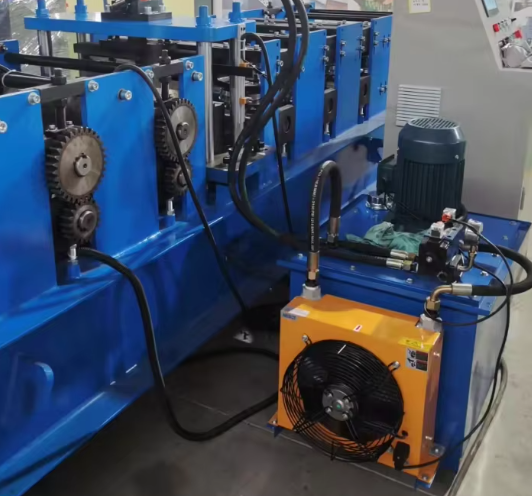

9.Transmission :By double chain, with chain cover

10.Voltage:380V,50Hz,3 phase (customize)

Part 3:Hydraulic cutting system

1.Work type:Hydraulic

2.Driving method:By Cylinder

3.Motor power:5.5 kw

4.Cutting blade material :GB-Cr12 mould steel with quenched treatment

5.Cooling system:By fan

Part 4: PLC Control system

1.PLC and Touch screen:Delta, wold famous brand

2.Electrical components:Schneider

3.Operating language:English and Chinese(or as requested)

4.Function:You can set the orders on this part,changing product length and quantity,it is really easy to operate,and there are aviation plugs to make it much easier to install the machine while it arrived.