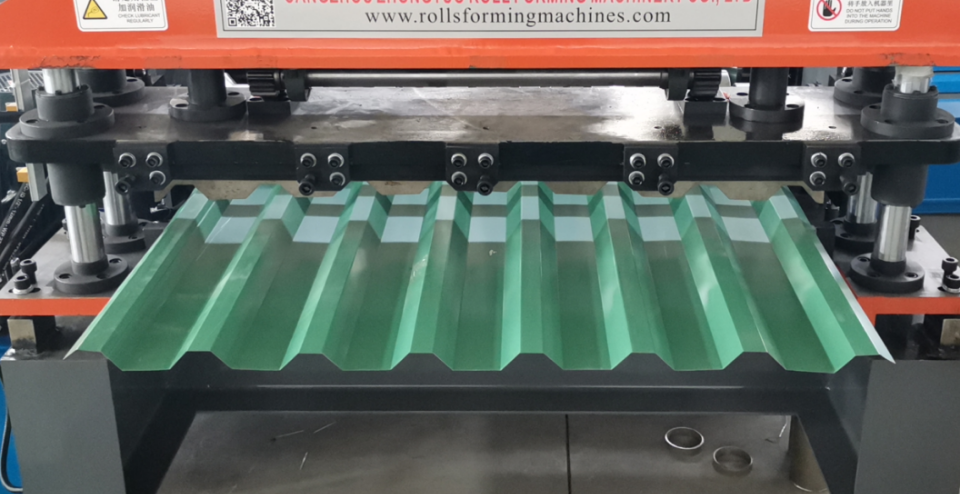

TR 101 Trapezoidal Roofing Sheet Making Machine Hot Sale in Mexico

The Zhongtuo TR101 Trapezoidal Roofing Sheet Making Machine adopts advanced production technology, which can greatly improve production efficiency. The roof tiles produced by our machines have excellent drainage performance, durability, wind resistance, and corrosion resistance, which enable trapezoidal tiles to perform well in various climatic conditions and extend the service life of the roof.

Our production line adopts continuous roll production after cold bending, which can ensure the shape regularity and length consistency of long cut parts. The formed products have good appearance and high precision.

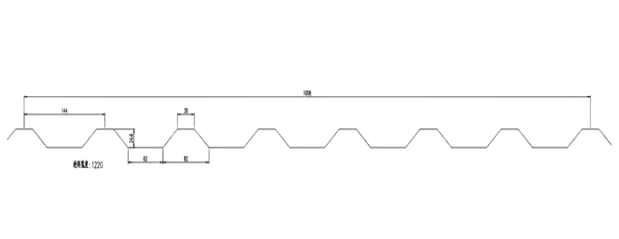

Profile drawing of TR 101 Trapezoidal Roofing Sheet Making Machine:

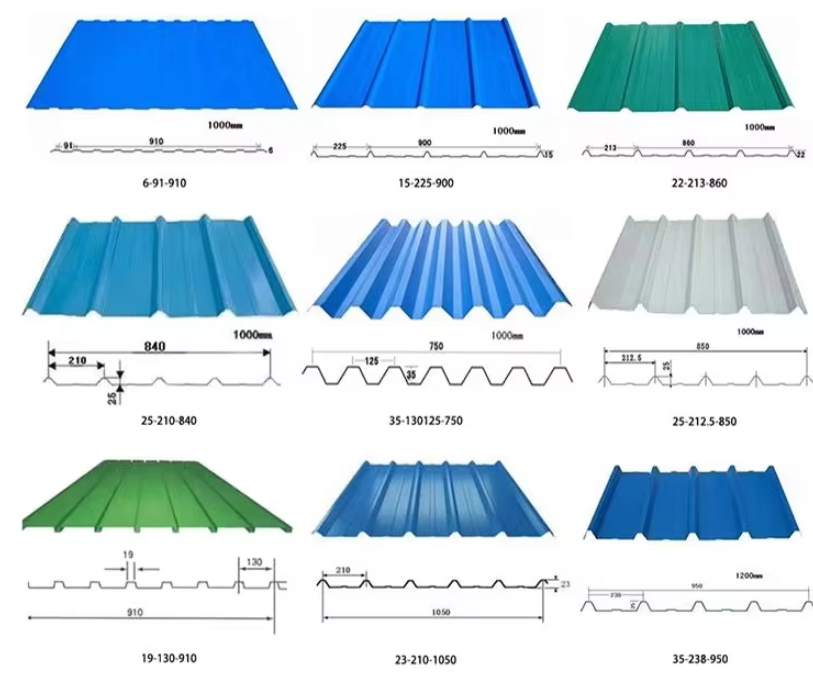

We have other pattern designs for you to choose from:

The TR101 Trapezoidal Roofing Sheet Making Machine also has the following characteristics:

- Automated control:

Equipped with advanced computer control systems, it can accurately control parameters such as material thickness, rolling speed, and shear length, ensuring the accuracy of product dimensions and the stability of quality. - Efficient production:

With efficient rolling technology and fast mold replacement capability, it helps reduce downtime and improve overall productivity. - Material adaptability:

It can handle different types of metal materials, such as galvanized steel plates, color coated steel plates, etc., suitable for the anti-corrosion and decoration requirements of different construction projects.

Packing list of the TR101 Trapezoidal Roofing Sheet Making Machine:

| No. | Name | Quantity |

| 1 | Manual/hydraulic Decoiler | 1 set |

| 2 | Main roll former | 1 set |

| 3 | Control system | 1 set |

| 4 | Hydraulic system | 1 set |

| 5 | Product Run-out table | 1 set |

The technical specifications of the TR101 Trapezoidal Roofing Sheet Making Machine:

| Item | Name | Specifications |

| 1 | Raw material | PPGI、PPGL |

| 2 | Raw material thickness | 0.4-0.6mm |

| 3 | Decoiler | 5T |

| 4 | Felt device | Available |

| 5 | Roller station | 21stations |

| 6 | Roller material | 45# steel; precision machining; chromium plating treatment |

| 7 | Shaft diameter | 80mm |

| 8 | Shaft material | 45# steel; precision machining |

| 9 | Transmission | by chains |

| 10 | Motor power | 5.5kw |

| 11 | Machine frame | 350H steel welded |

| 12 | Cutting type | Hydraulic cutting |

| 13 | Hydraulic power | 5.5kw |

| 14 | Cutting blade material | Cr12 with quenched treatment |

| 15 | Cutting tolerance | +/-1mm |

| 16 | Control system | PLC |