TR4 Trapezoidal Roofing sheet Roll Forming Machine is produced for Peru customer,the features of this machine:

1.One machine can produce trapezoidal sheet.

2.One machine can use 1250mm width coil.

3.The finished product is absolutely flat after cut.

4.The voltage of this machine is 380V-50HZ-3P.

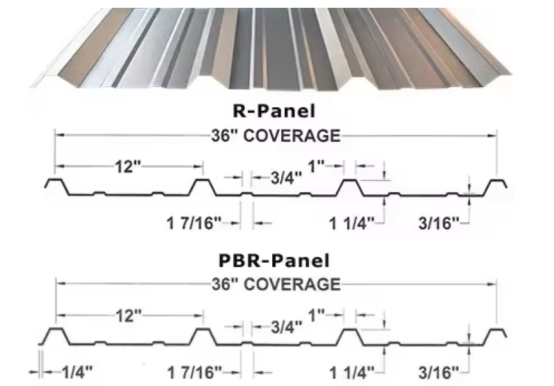

The profile drawing:

Packing list of the TR4 Trapezoidal Roofing sheet Roll Forming Machine:

| No. | Name | Quantity |

| 1 | Manual/hydraulic Decoiler | 1 set |

| 2 | Main roll former | 1 set |

| 3 | Control system | 1 set |

| 4 | Hydraulic system | 1 set |

| 5 | Product Run-out table | 1 set |

The technical specifications of the TR4 Trapezoidal Roofing sheet Roll Forming Machine:

| Item | Name | Specifications |

| 1 | Raw material | PPGI/GI |

| 2 | Raw material thickness | 0.4-0.9 mm |

| 3 | Decoiler | 5T |

| 4 | Felt device | Available |

| 5 | Roller station | 19stations |

| 6 | Roller material | 45# steel |

| 7 | Shaft diameter | 80mm |

| 8 | Shaft material | 45# steel |

| 9 | Transmission | By double chains |

| 10 | Motor power | 5.5kw |

| 11 | Machine frame | 350H steel welded |

| 12 | Cutting type | Hydraulic cutting |

| 13 | Hydraulic power | 3kw |

| 14 | Cutting blade material | Cr12 with quenched treatment |

| 15 | Cutting tolerance | +/-1mm |

| 16 | Control system | Delta/ Siemens PLC |

The function of the TR4 Trapezoidal Roofing sheet Roll Forming Machine:

1. Efficient production:

The TR4 Trapezoidal Roofing sheet Roll Forming Machine is designed to be efficient and capable of producing a large number of trapezoidal roof tiles in a short period of time, suitable for large-scale production needs.

2.High quality output:

Through advanced rolling forming technology and PLC control system, precise control and automation of the production process are ensured, reducing labor costs and improving productivity.

3.Strong durability:

The machine uses advanced 45 steel as the drum material and 350H steel for the main frame, ensuring durability and long life.

4. Customized services:

Provide customized color options to meet the diverse needs of customers.